About Us

About Manasota Optics, Inc.

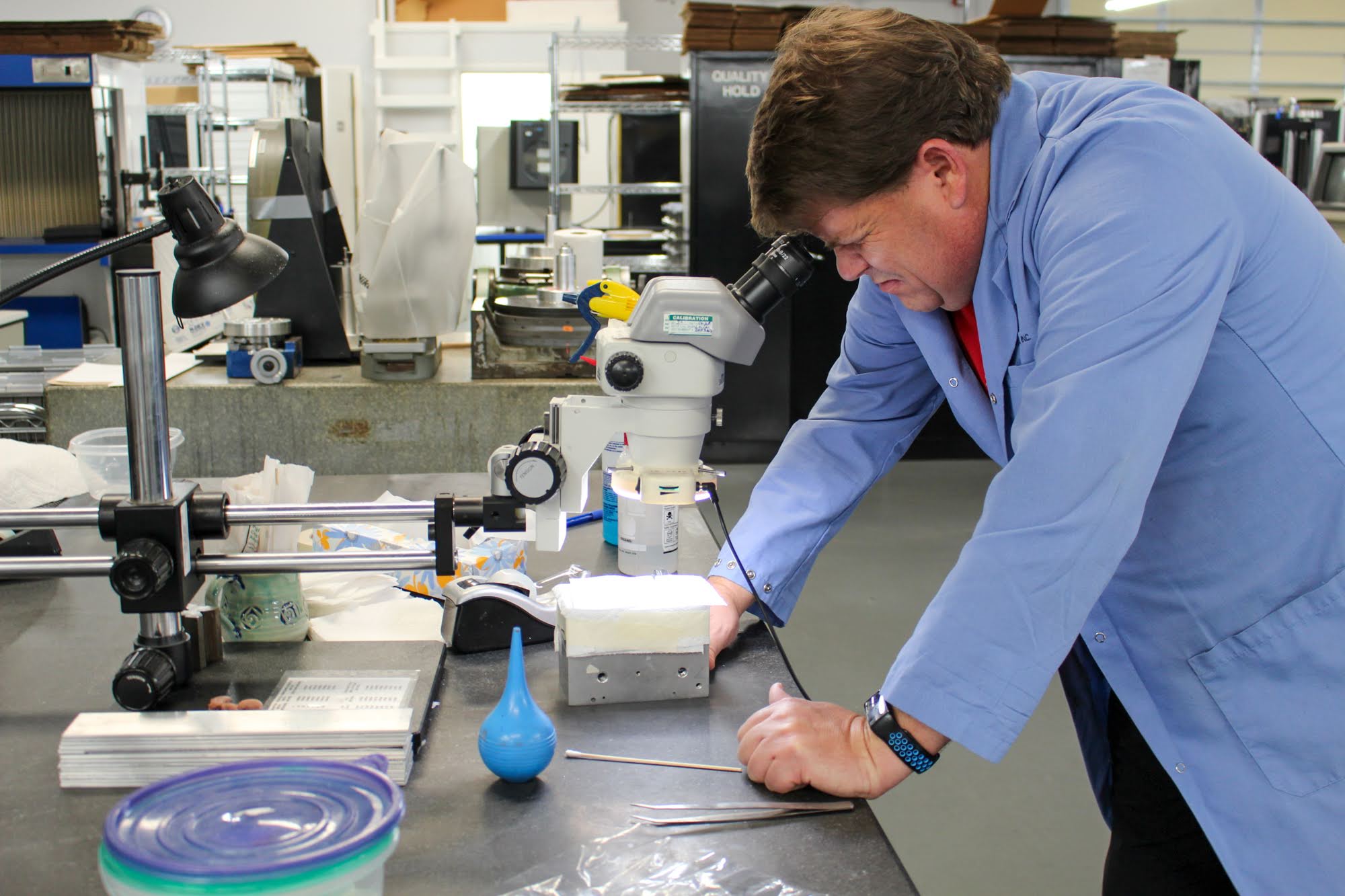

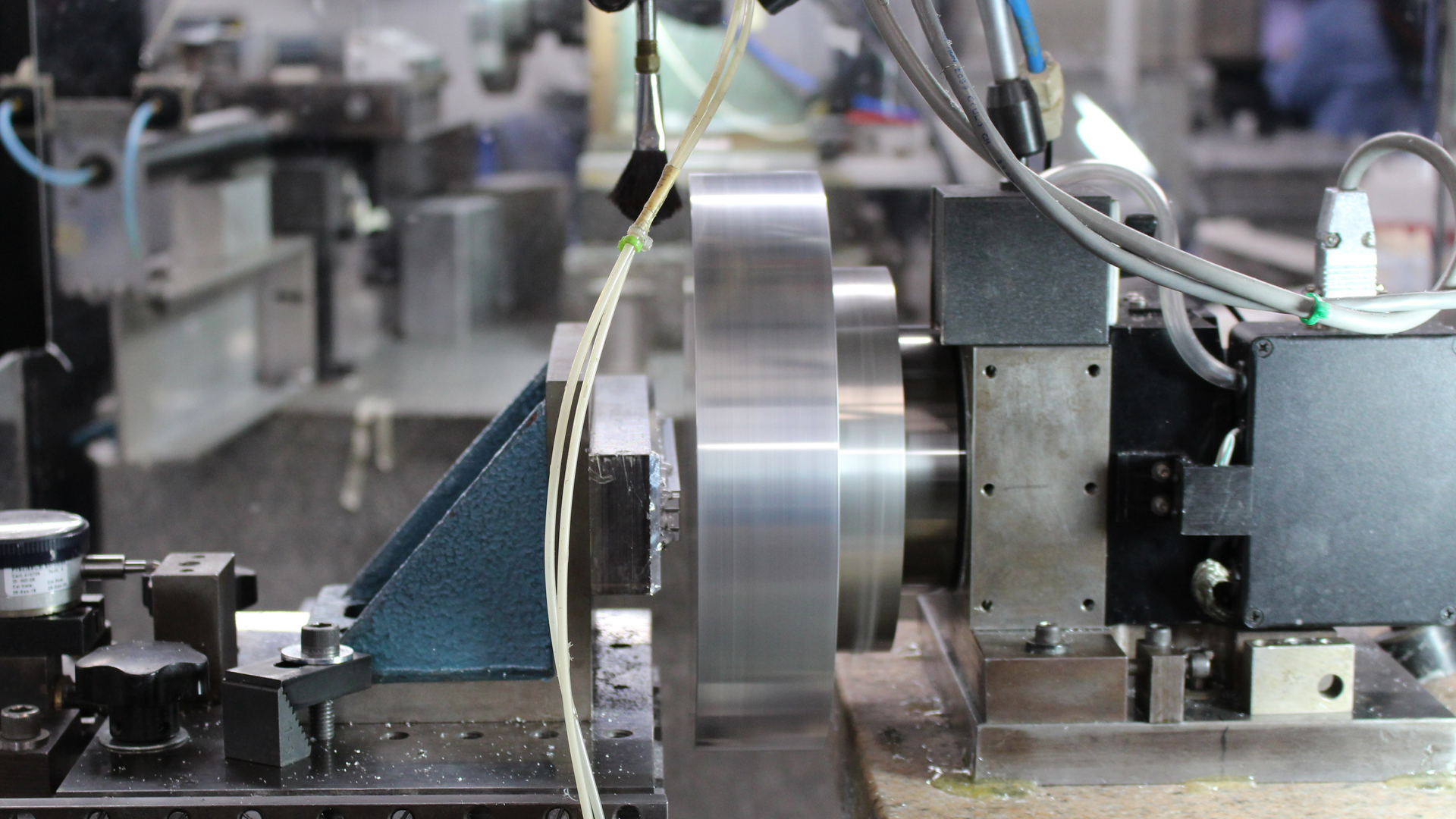

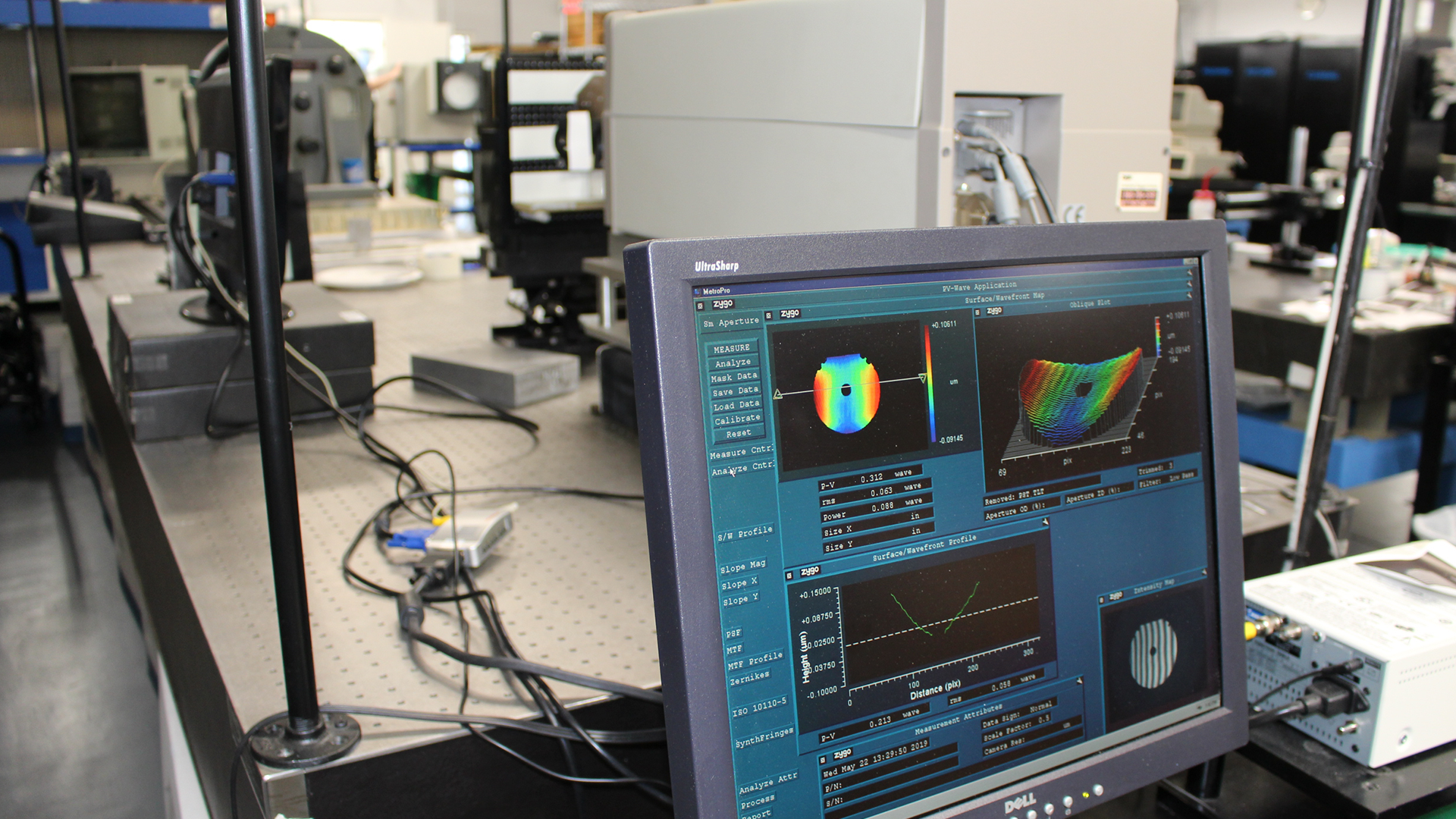

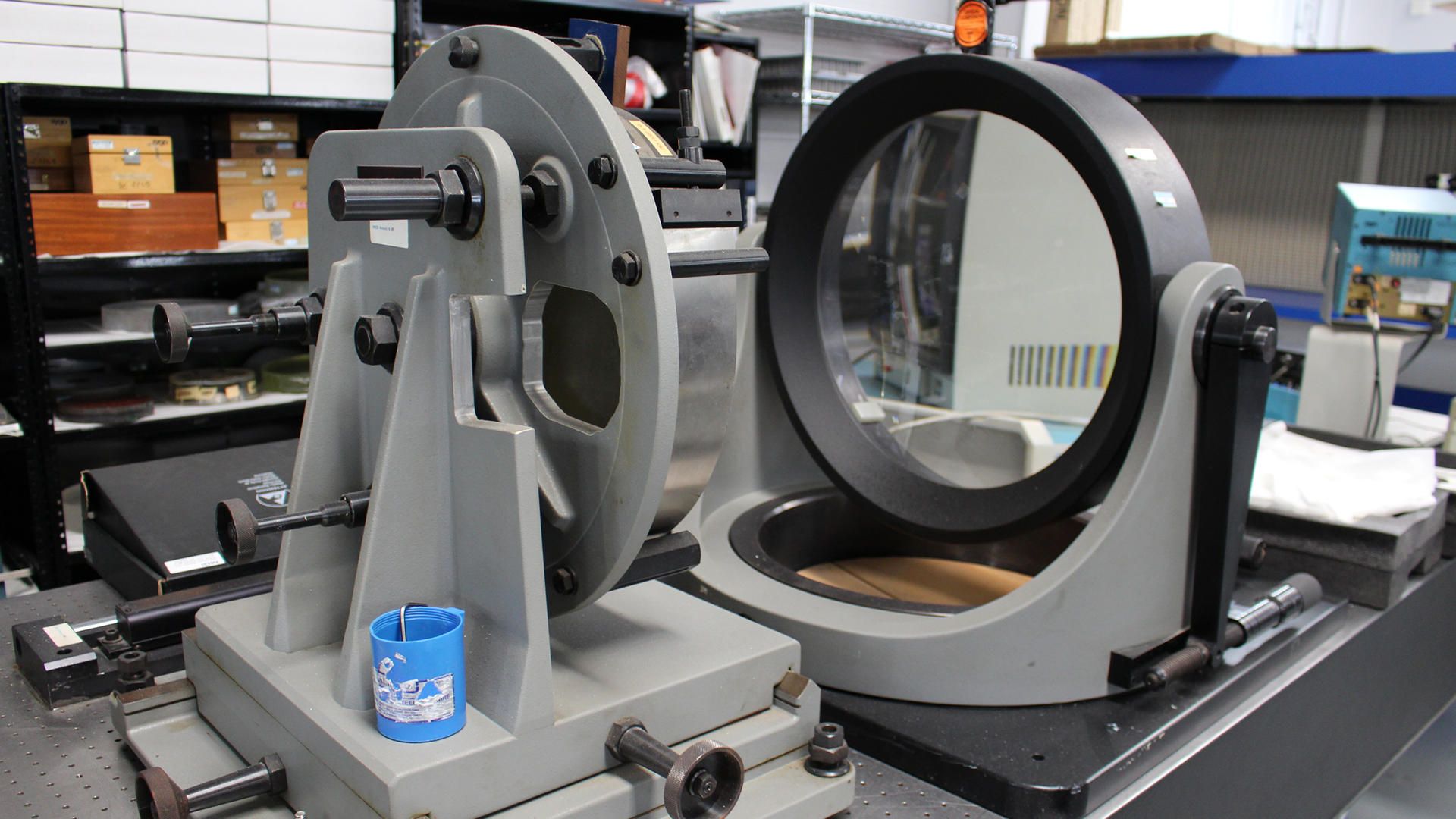

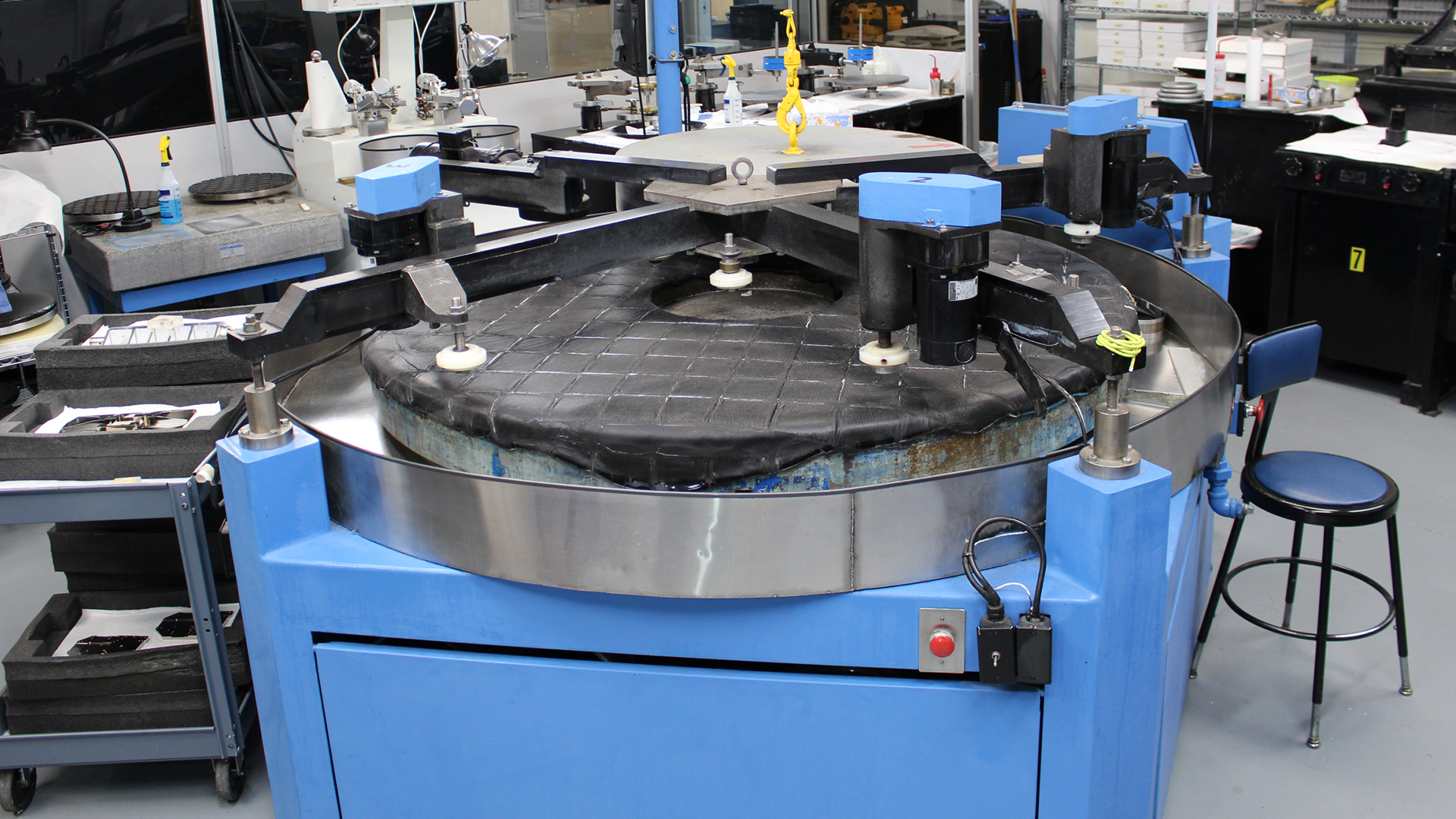

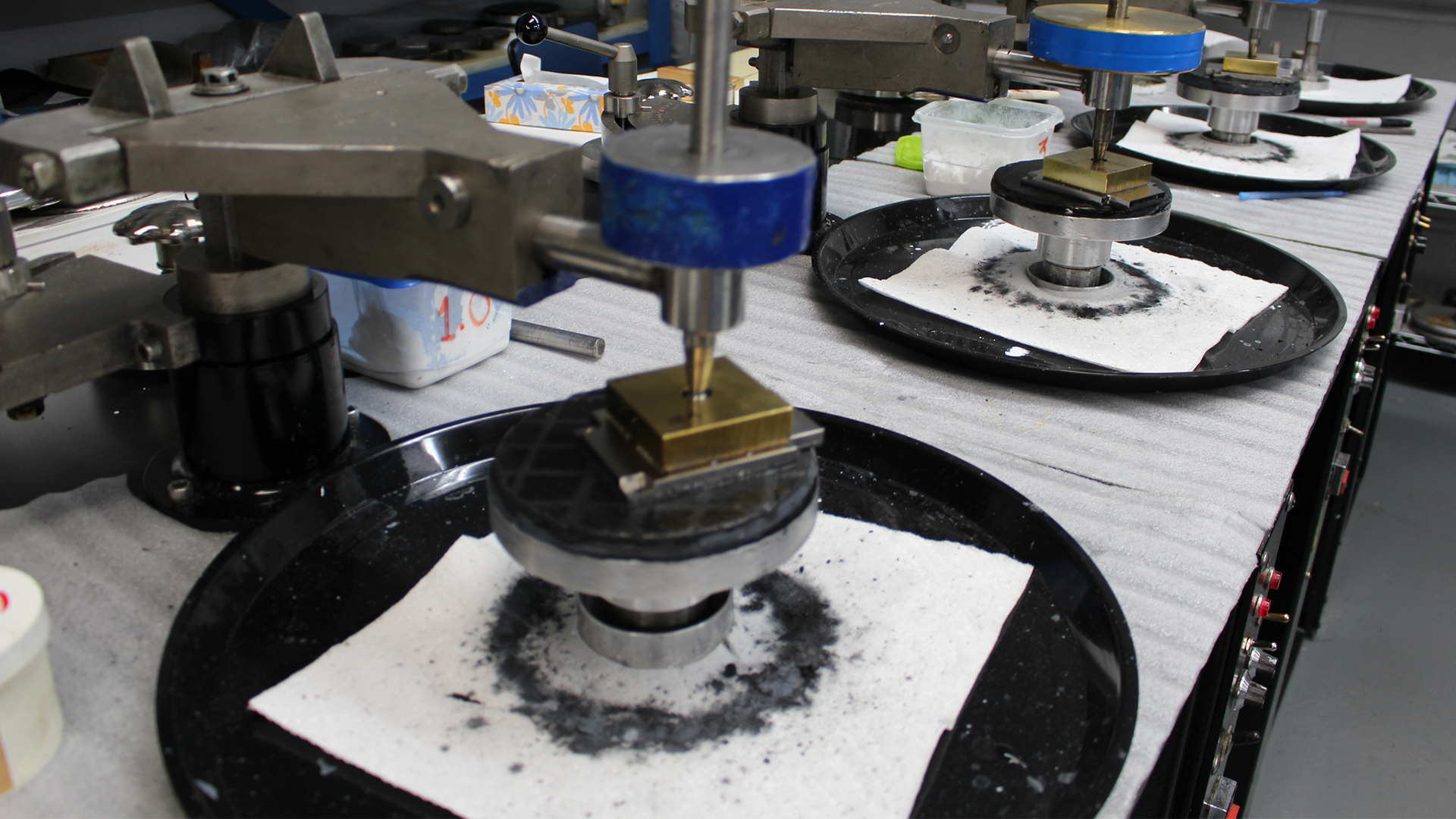

Manasota Optics, Inc. (MOI) is a “build to print” manufacturer of metal optical components that are used in the Defense and Aerospace Sector. MOI fabricates metal optical components for Military and Commercial Applications that are used in various sighting systems. These include laser rangefinders, targeting and infrared countermeasure systems, scanners, biological & chemical detection systems and space applications.

MOI is a key supplier to many US Prime Defense Contractors and Defense Contractors to the German and Turkish Governments.

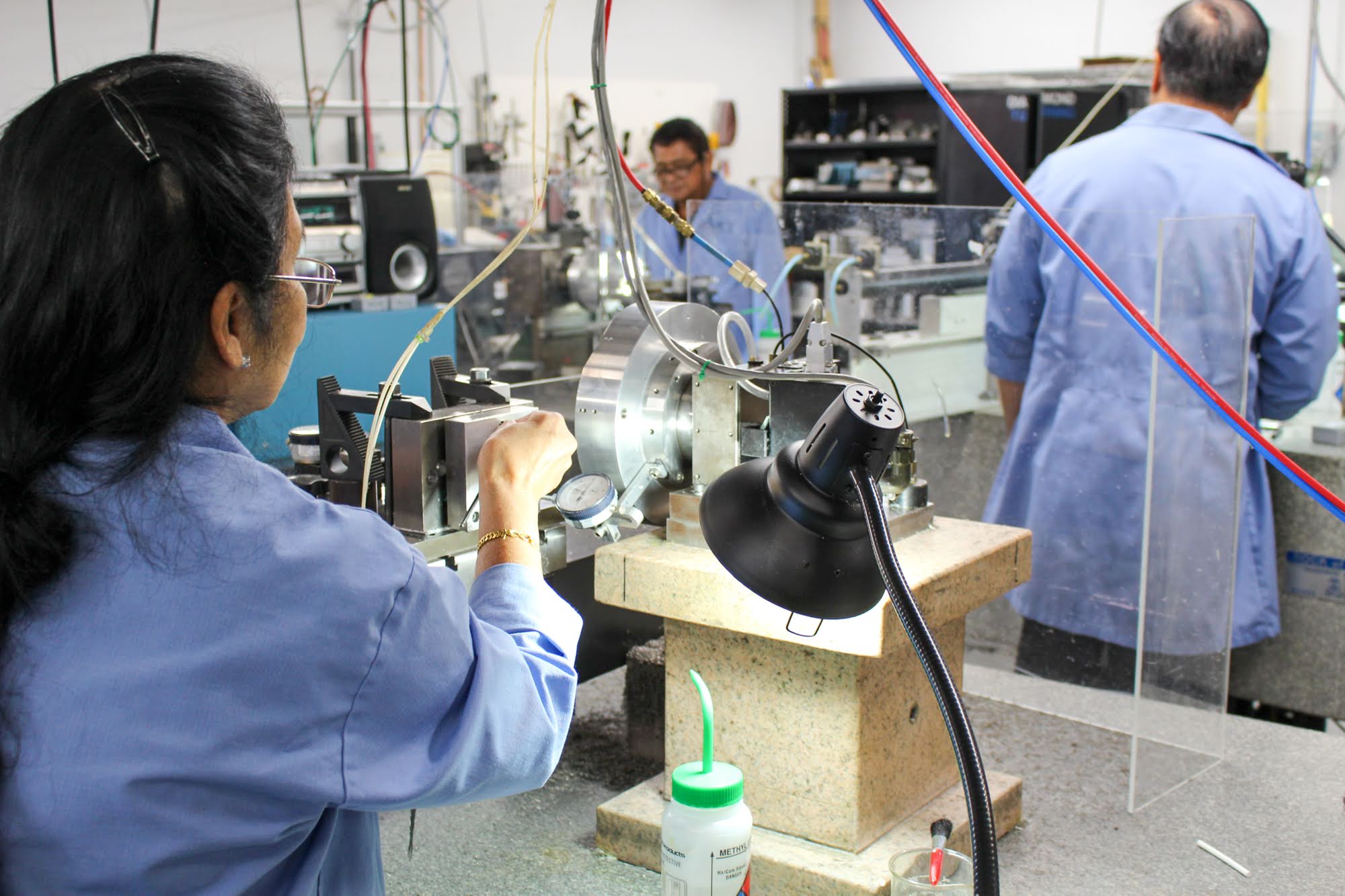

MOI’s quality and delivery rating is near 100% with our customers. This is achieved by our talented production employees, most of which have 30-35 years’ experience with metal optics.

Currently MOI is a build to print manufacturer but has extensively worked with many customers through engineering and procurement to create a product that is not only functional but is also cost efficient.

Our manufacturing facility and administrative offices are located in Sarasota, Florida. We are located within 5 miles of the Bradenton / Sarasota International Airport and about 55 miles from the Tampa International Airport.

Manasota Optics has an export license though the Department of State and exports optical components overseas to Turkey as well as Germany.

Download PDF of our Quality Policy

Download PDF of our Quality Manual

Certifications

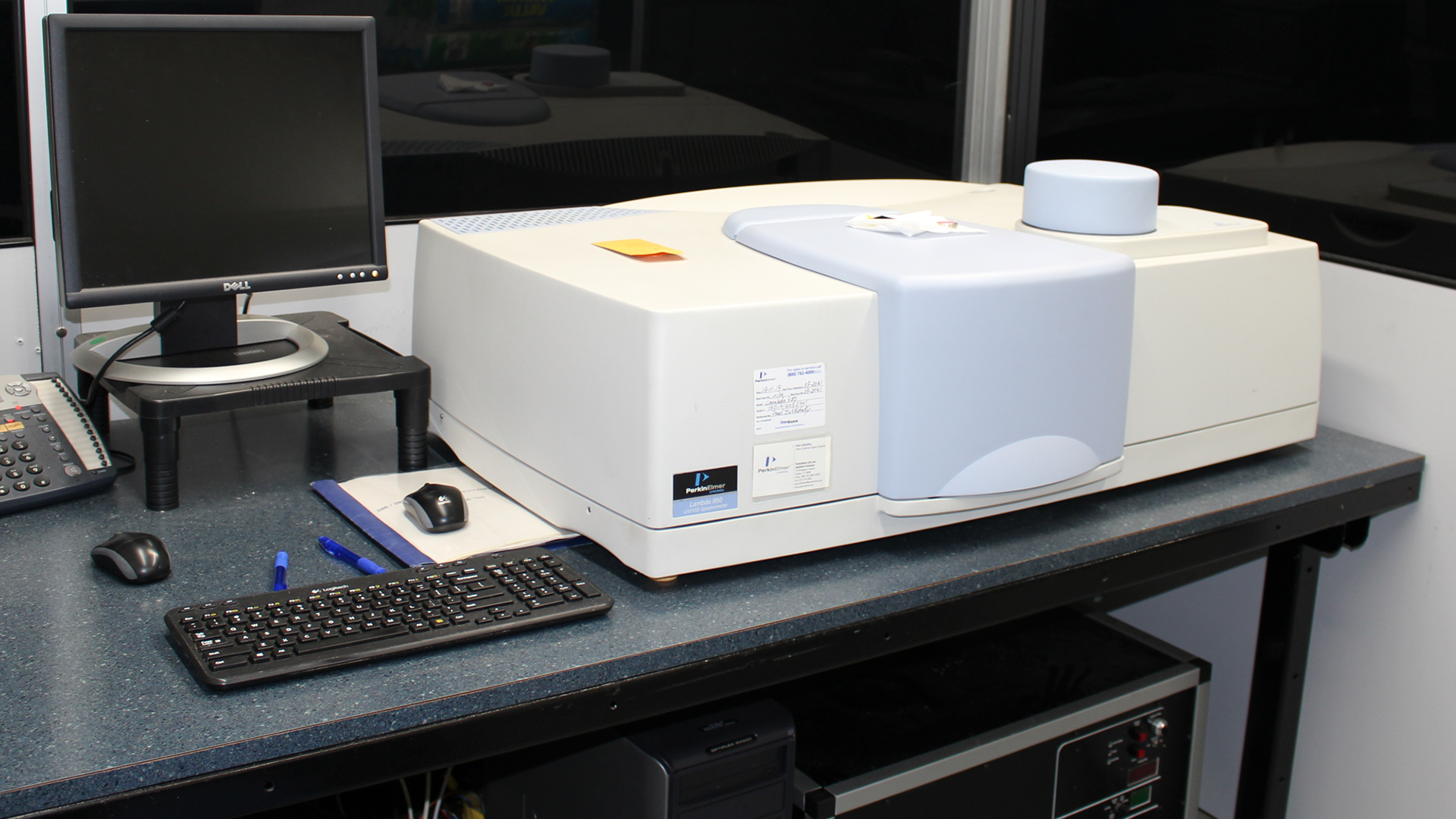

Manasota Optics is proud to hold many certifications that demonstrate MOI’s ability to consistently provide products and services that meet customer, statutory and regulatory requirements.

Our Mission

Our mission is to provide our customers products that are second to none in our industry. The vast experience with metal optics that we possess has allowed us to evaluate our customer’s design for manufacturability which in return creates a functional, but cost-efficient product that is delivered to our customers when promised.

Quality Policy

Our mission is to provide our customer a product which is second to none in the metal optics industry. It is our personal commitment to deliver a defect free, on time product at the most competitive price within our business sector. Our objective is not only to meet our customer’s quality standards, but to be the standard for others.

Business Standards

Manasota Optics Inc. (“MOI”) is an ISO 9001:2015 certified build to print manufacturer. MOI requires all vendors, suppliers, and subcontractors (“Supplier(s)”) to adhere to all applicable laws and regulations which apply to their performance or supply of materials or parts to MOI. The purpose of these Business Standards / Supplier Code of Conduct (the “Standards”) is to provide guidelines for the performance and

supply by a MOI Supplier.

History

Established in 1994, Manasota Optics, Inc. was founded by David Lowery, a Navy Veteran, after acquiring assets from Applied Optics Center which was closed by IMO Industries (AOC’s parent company in 1993). MOI is comprised of personnel with 30 – 35 years’ experience. We employ industry professionals in diamond turning, polishing, and coating of flat “plano” and spherical metal optical components. In 2014, MOI became a majority woman owned business and continue to operate at ISO 9001:2015 certified standards.