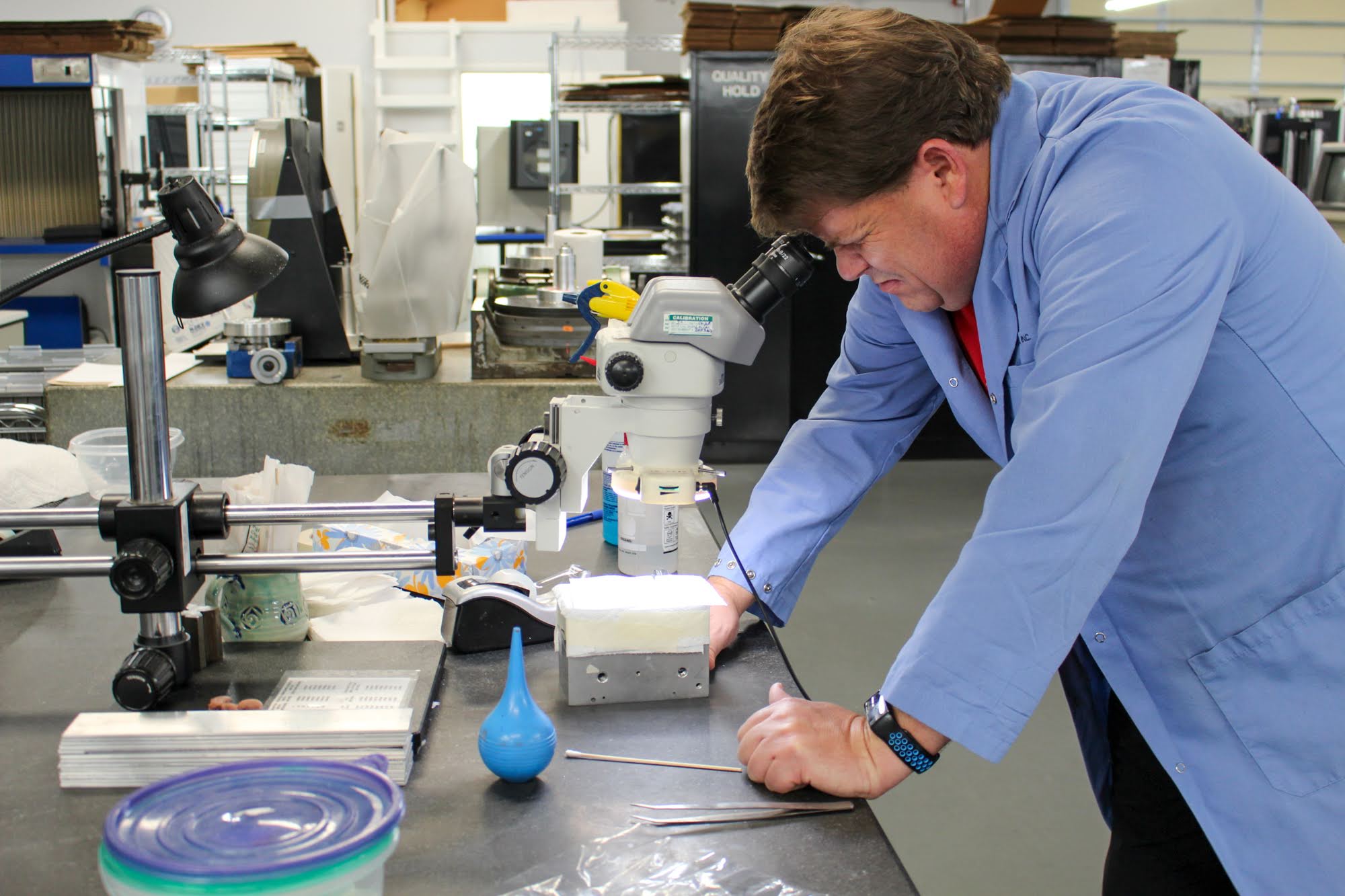

Polishing and Grinding

Polishing and Grinding Capabilities from Manasota Optics

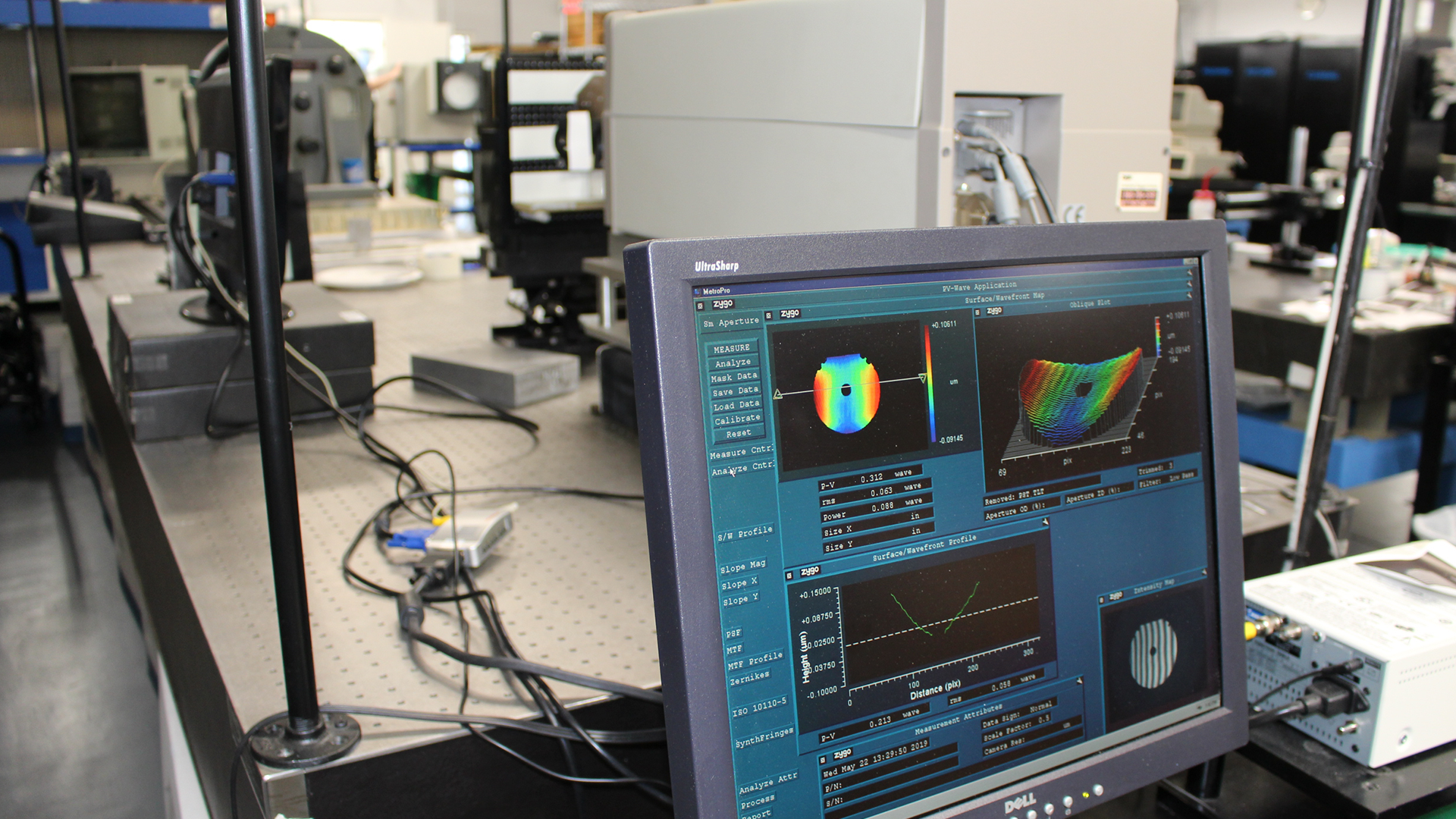

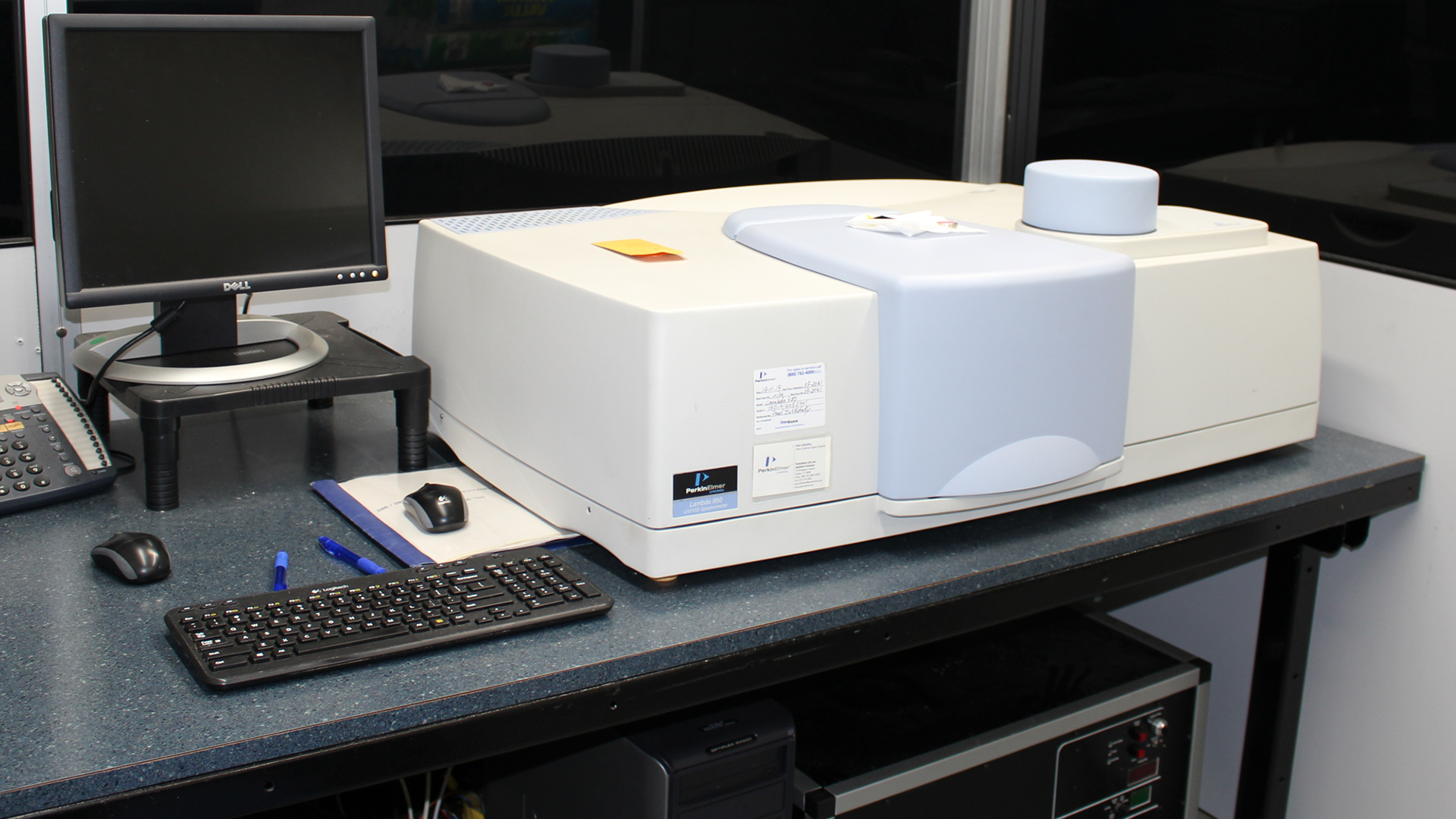

Manasota Optic’s Polishing and Grinding services can produce “plano” or flat optics as well as spherical components. The sizes of components can range up to 24″ in diameter and the optical requirements are typically 1/8 wave or better PV and 20-40 angstroms RMS for surface roughness.

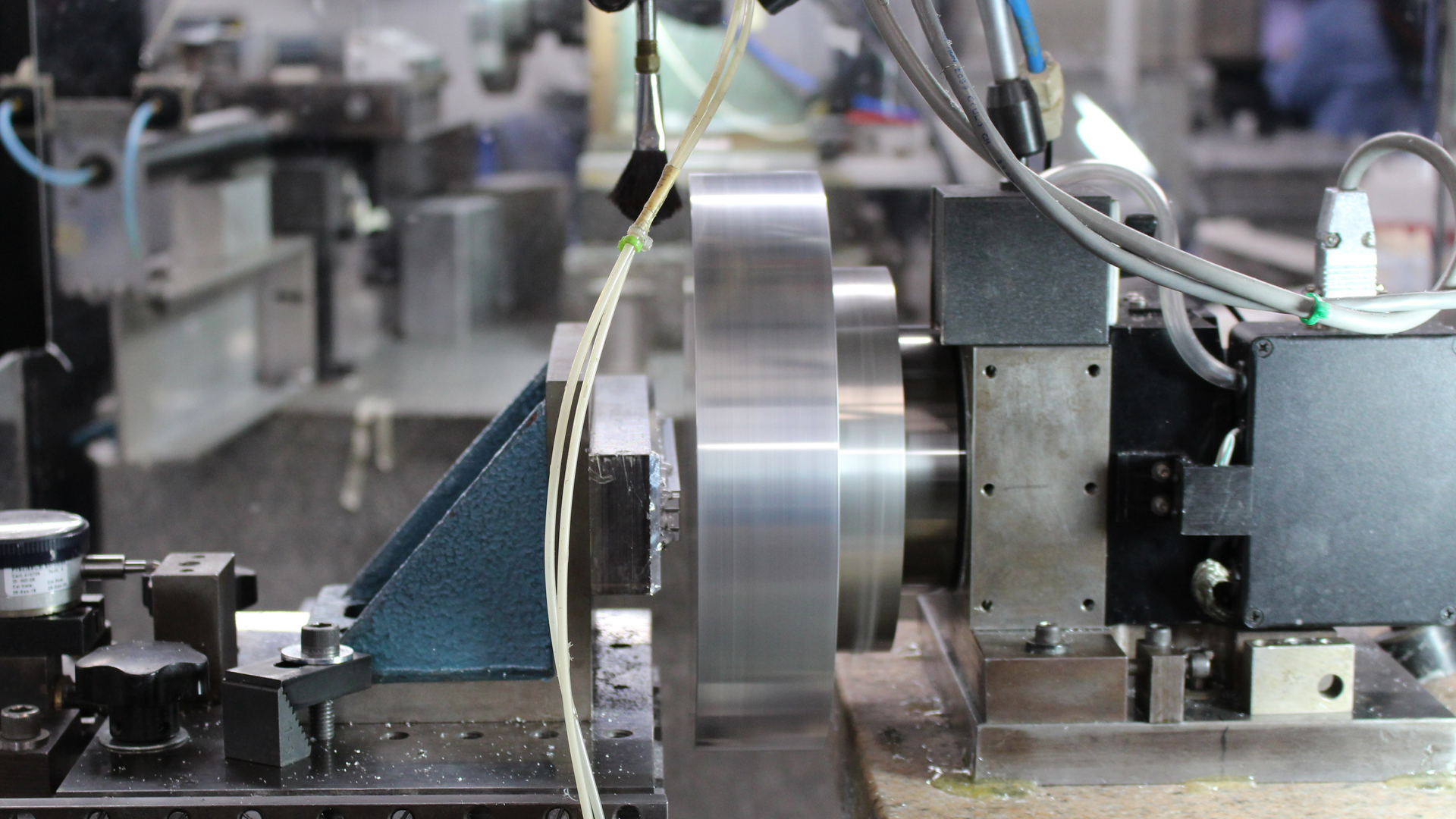

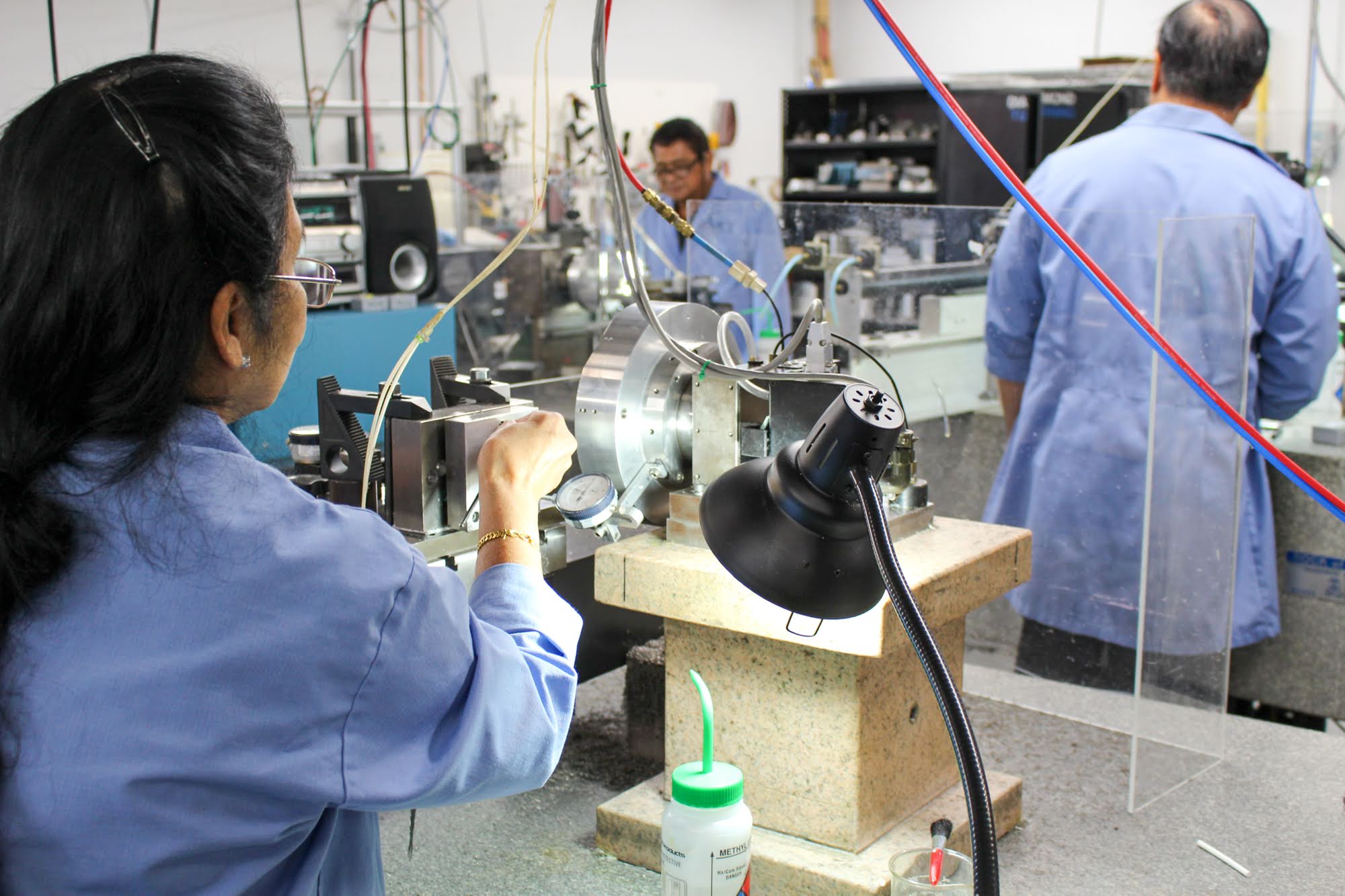

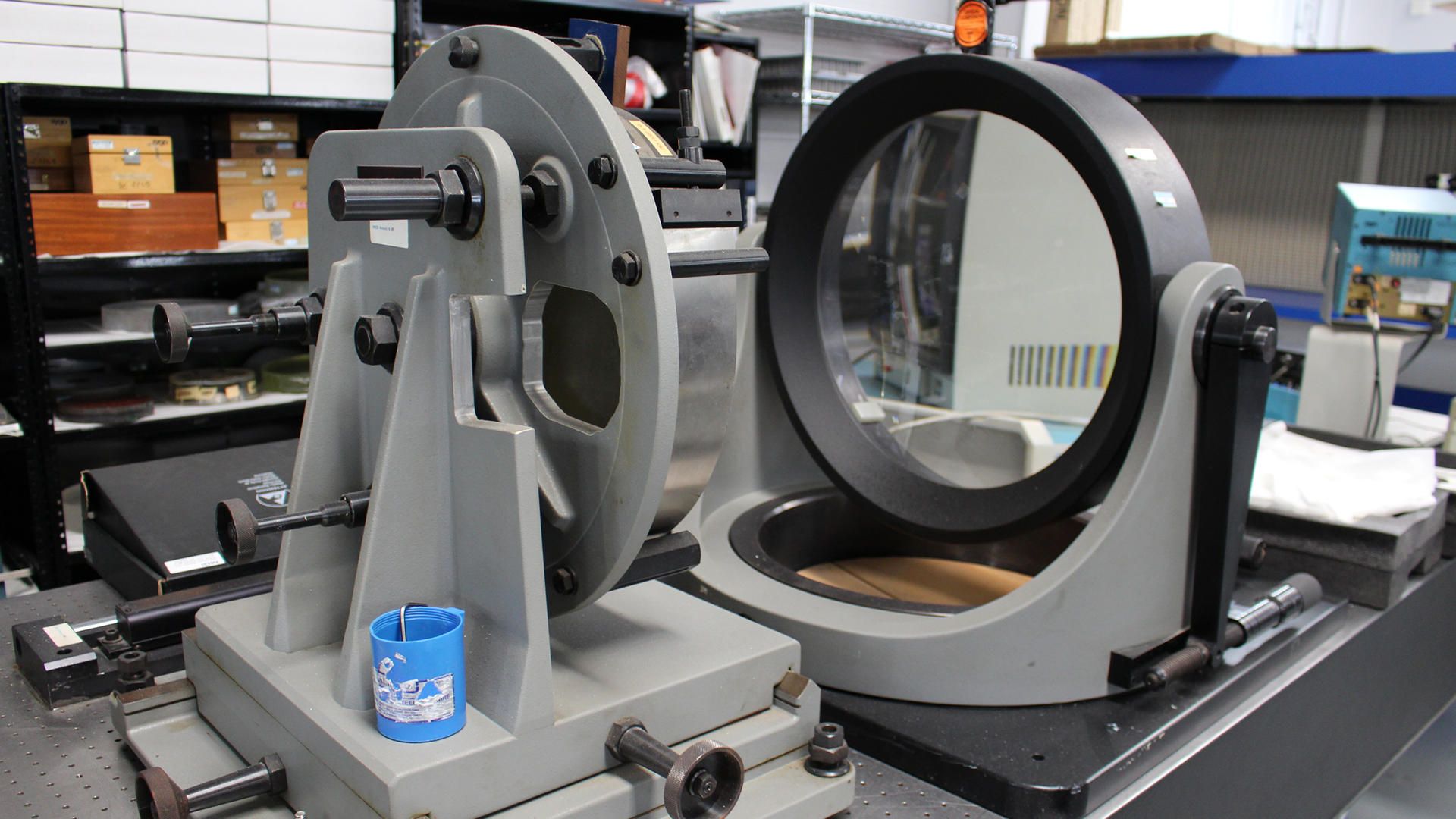

Polishing and Grinding Equipment

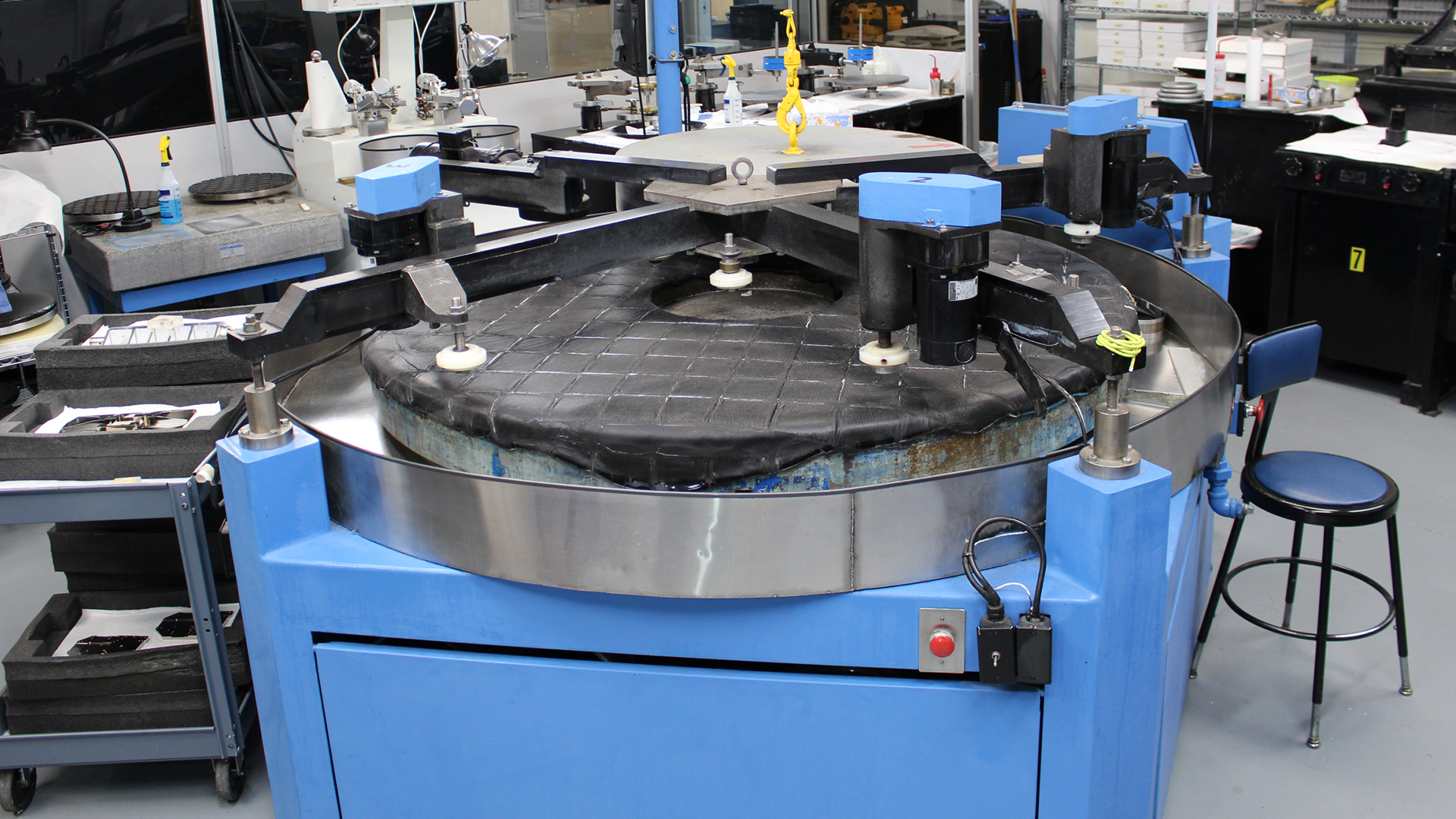

- 72″ Strasbaugh Planetary Polisher

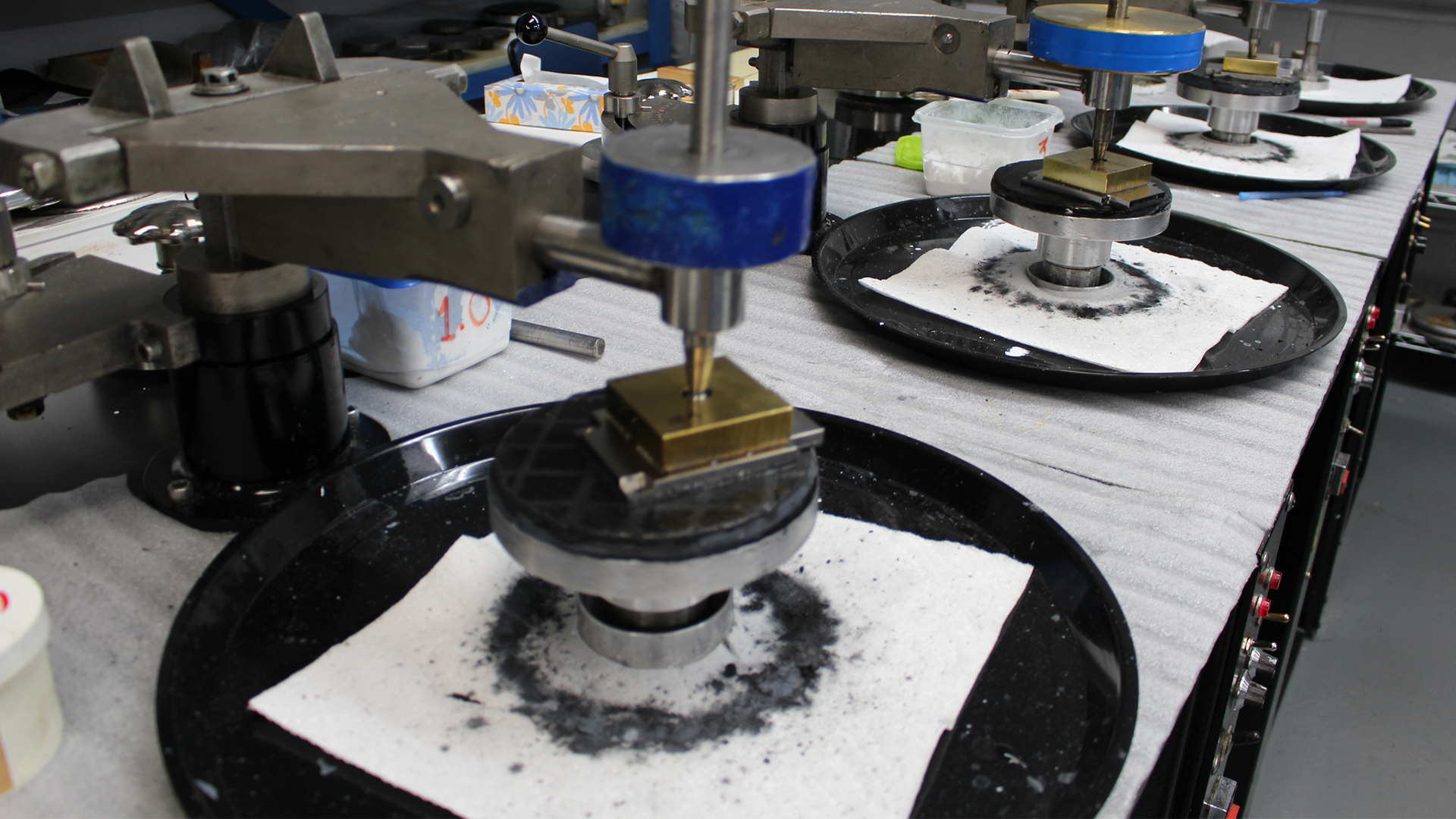

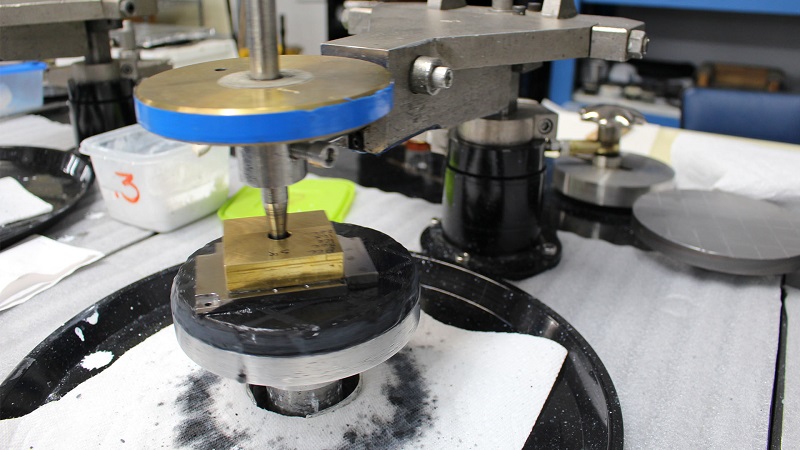

- 9 Single Spindle Polishing / Lapping Machines

- 1 Dual Spindle Polishing / Lapping Machine

The planetary polisher has a lap surface which accommodates three 26” polishing rings, allowing us to polish three 24” mirrors at one time. MOI also has tooling capabilities to produce many smaller components within the 26″ ring. The flatness of the lap is controlled by a 40” conditioning granite rock, which results in controlled material removal and near identical flatness of the mirrors in the polishing rings.

The single and dual spindle machines give MOI the autonomy to run many different components simultaneously that have different sizes, shapes and or optical requirements.

Polishing and Grinding Materials

- Electroless Nickel Plated Substrates

- Copper

- A variety of Stainless Steels

- AlBeMet

- Titanium

Our Mission

Our mission is to provide our customers products that are second to none in our industry. The vast experience with metal optics that we possess has allowed us to evaluate our customer’s design for manufacturability which in return creates a functional, but cost-efficient product that is delivered to our customers when promised.