Diamond Turning

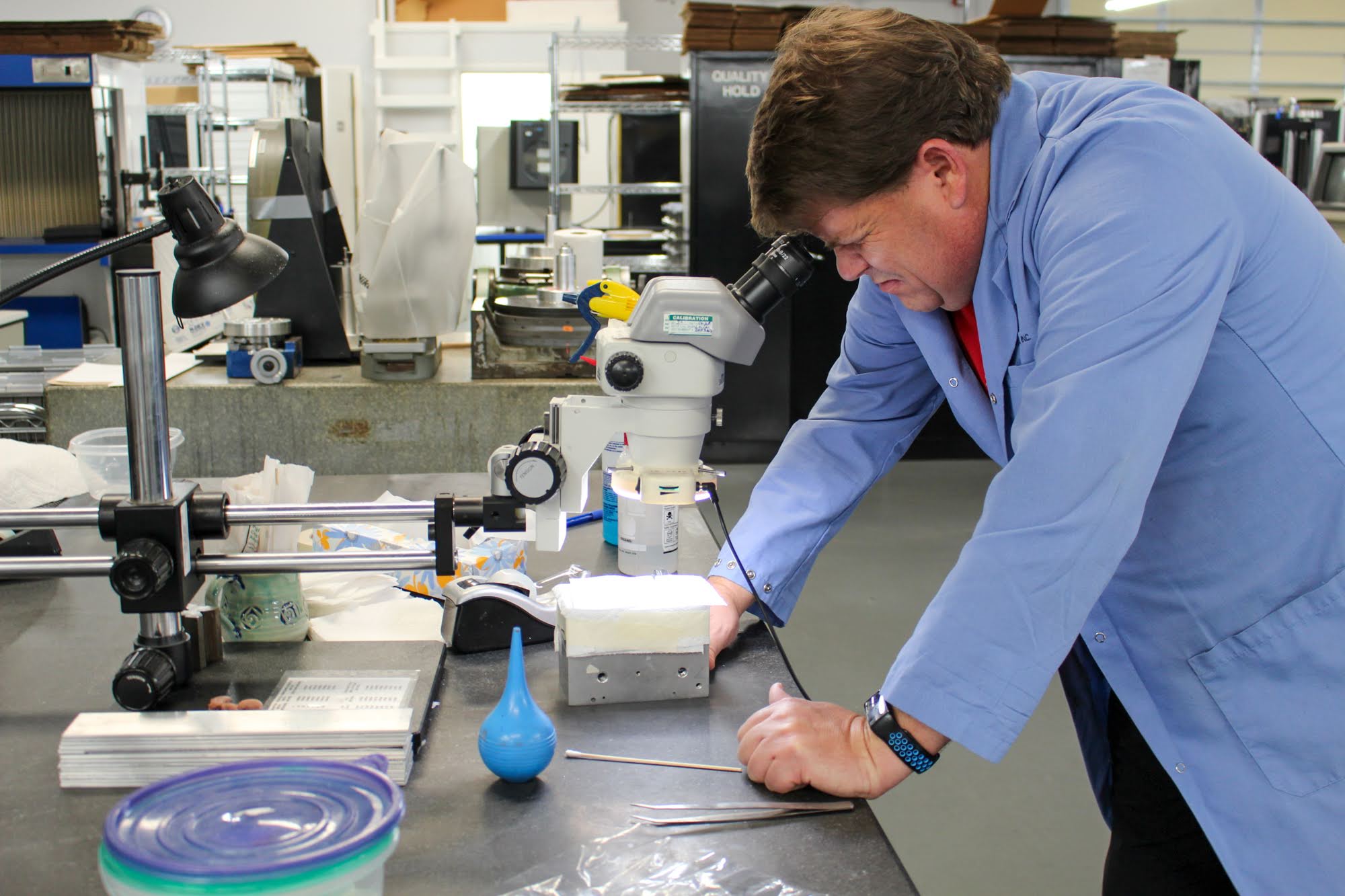

Diamond Turning Capabilities from Manasota Optics

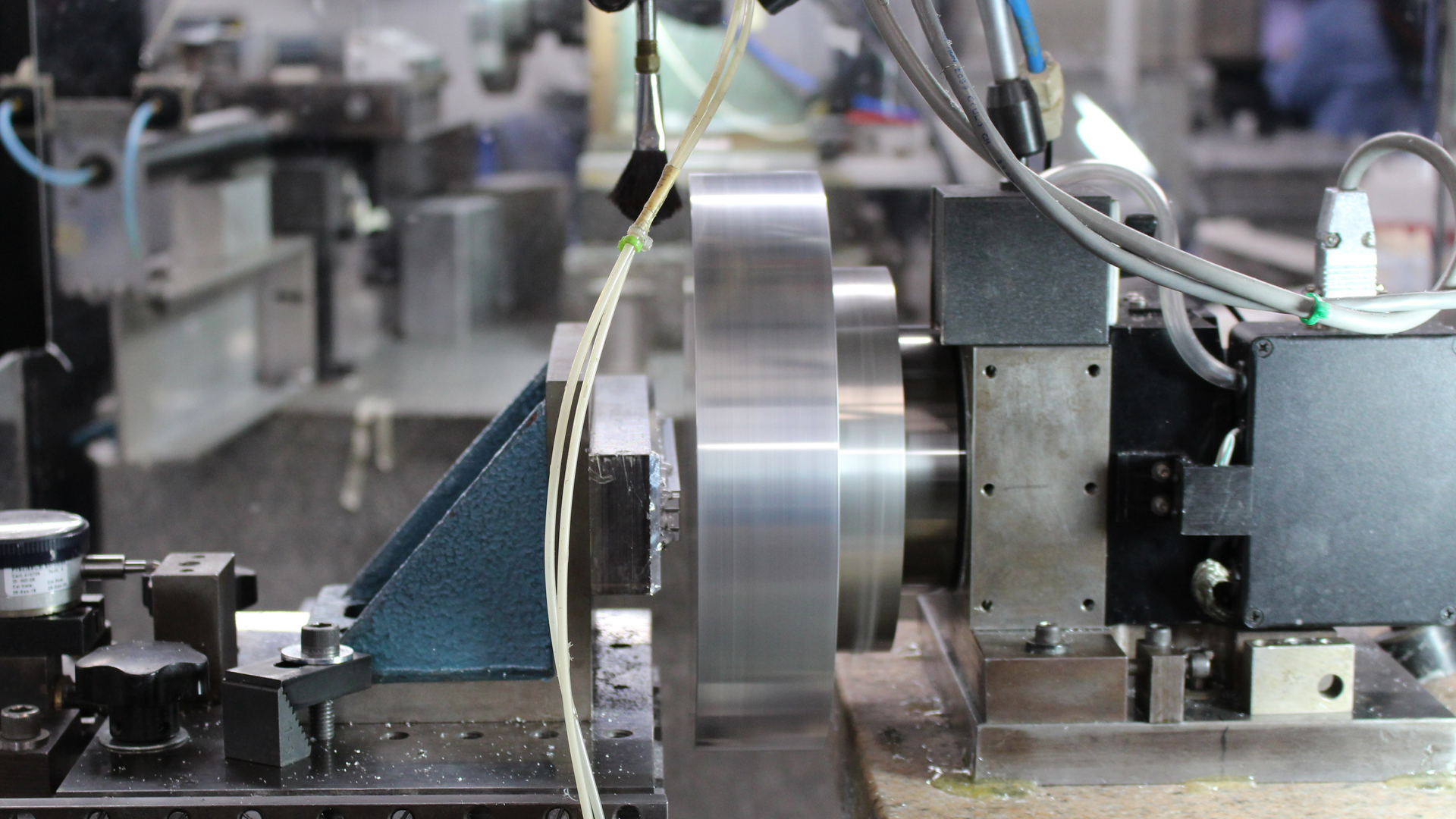

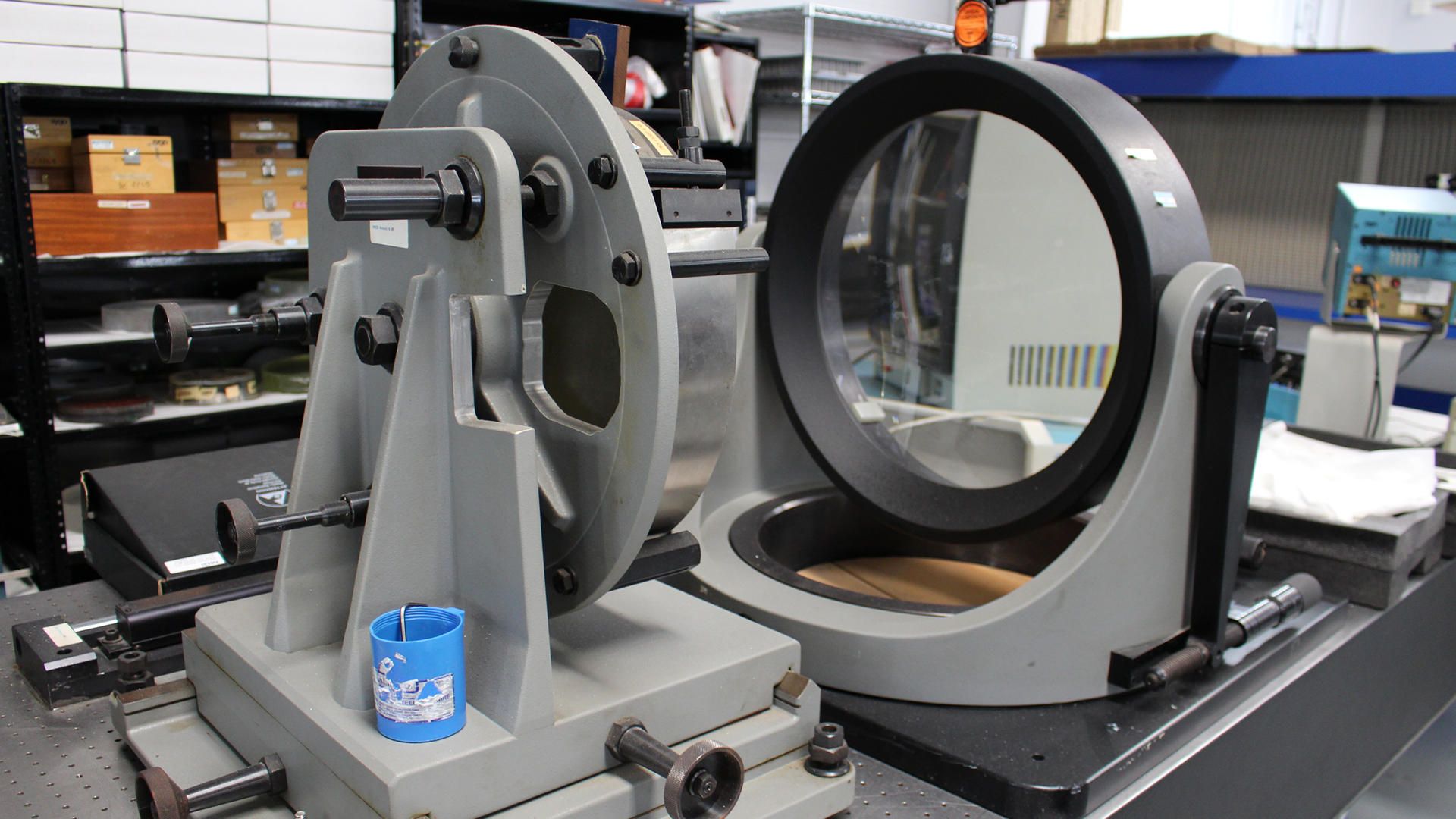

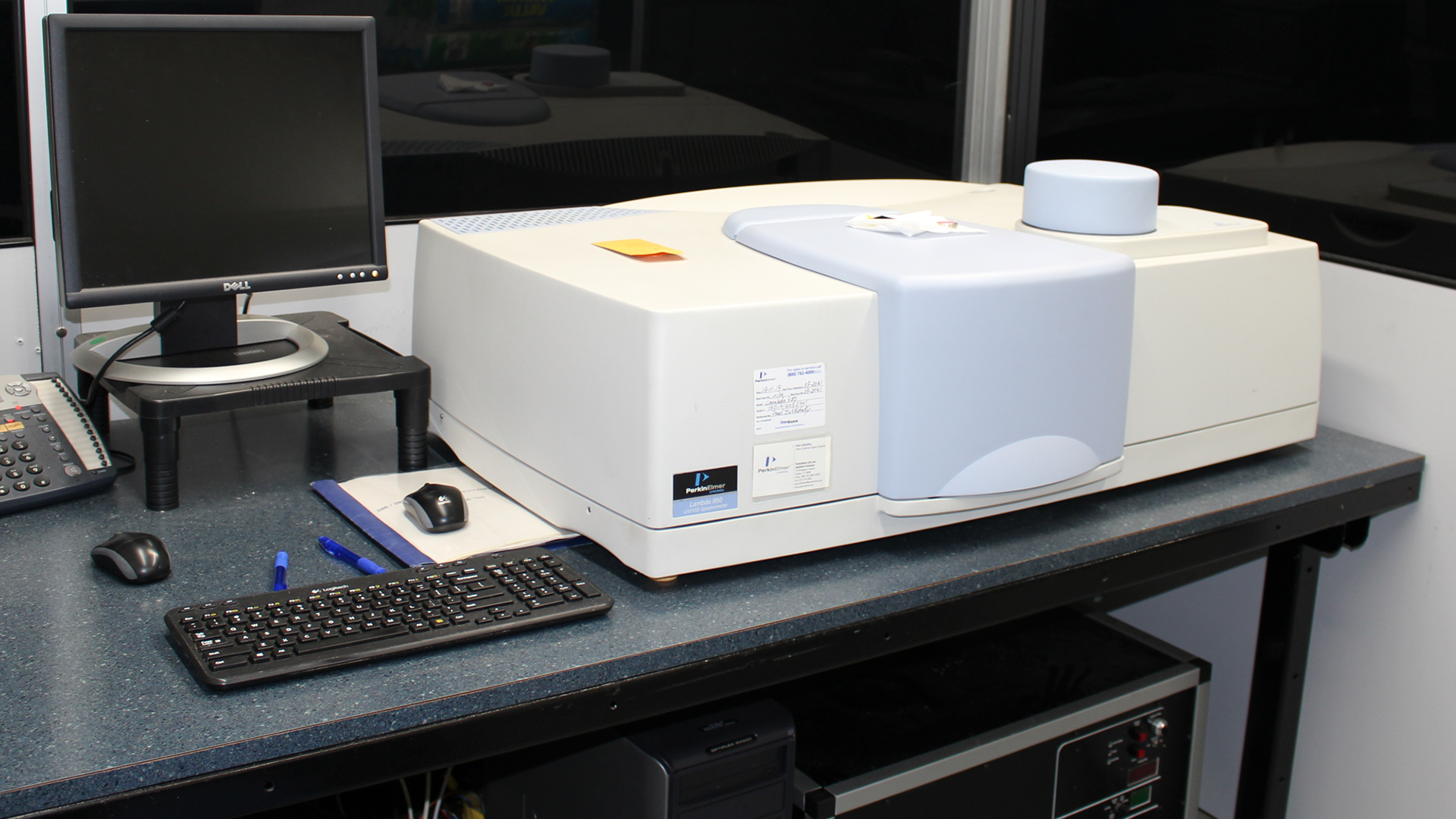

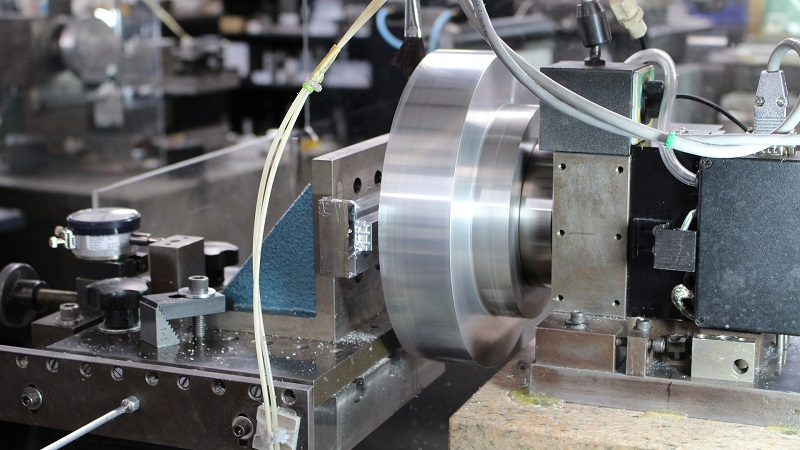

Manasota Optics’ Diamond Turning Equipment is made up of Custom-Built Single Point (SPDT) “Fly-Cutting” Machines. These machines work with a variety of materials, including Bare Aluminum 6061, 5052, and 7075, Electroless Nickel Plated Substrates, Copper, and Invar, to produce “plano” or flat optics.

Diamond Turning Equipment

- 6 SPDT machines with additional machines to be added in the near future

- Upgraded Controllers installed in 2009

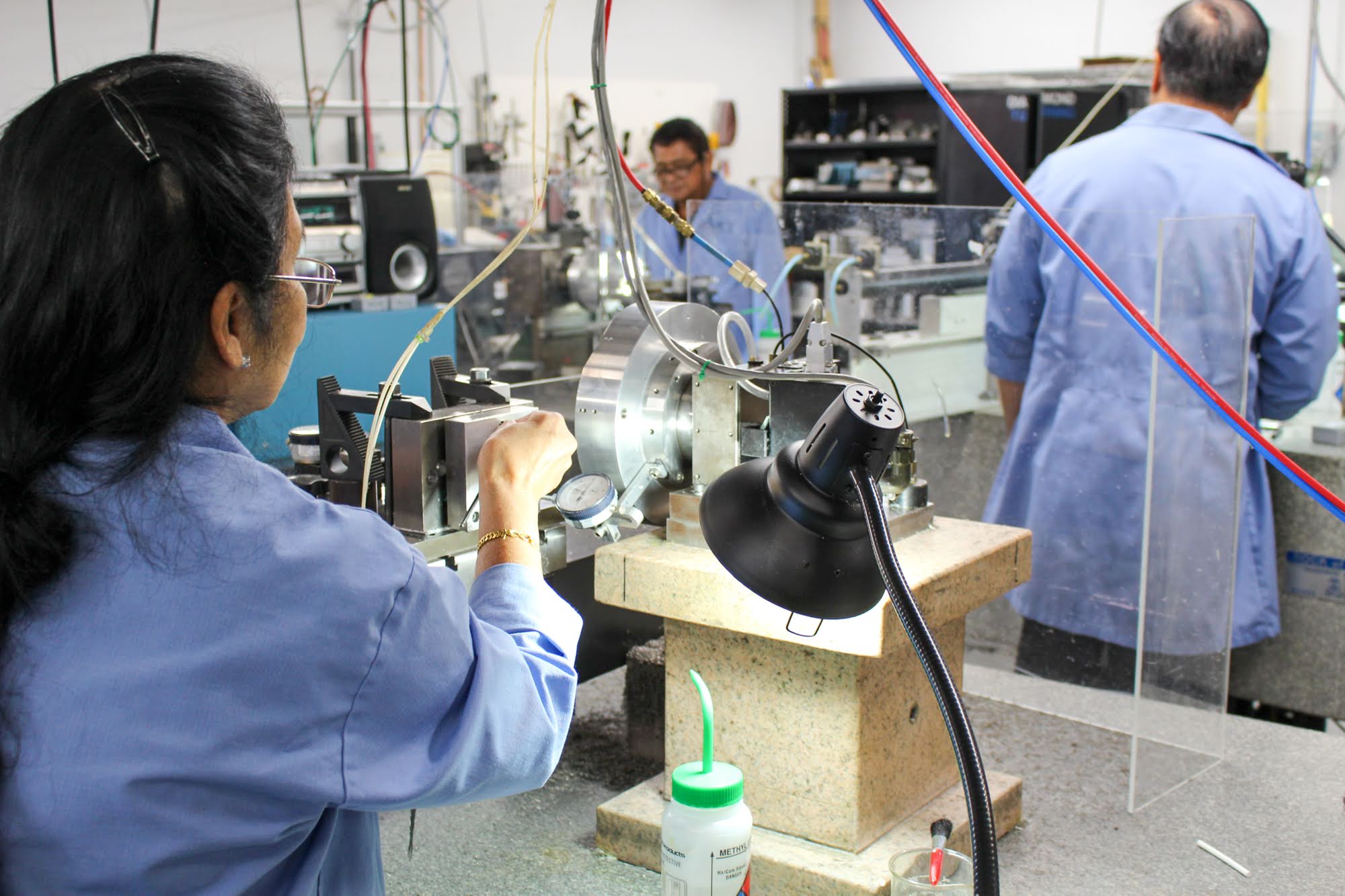

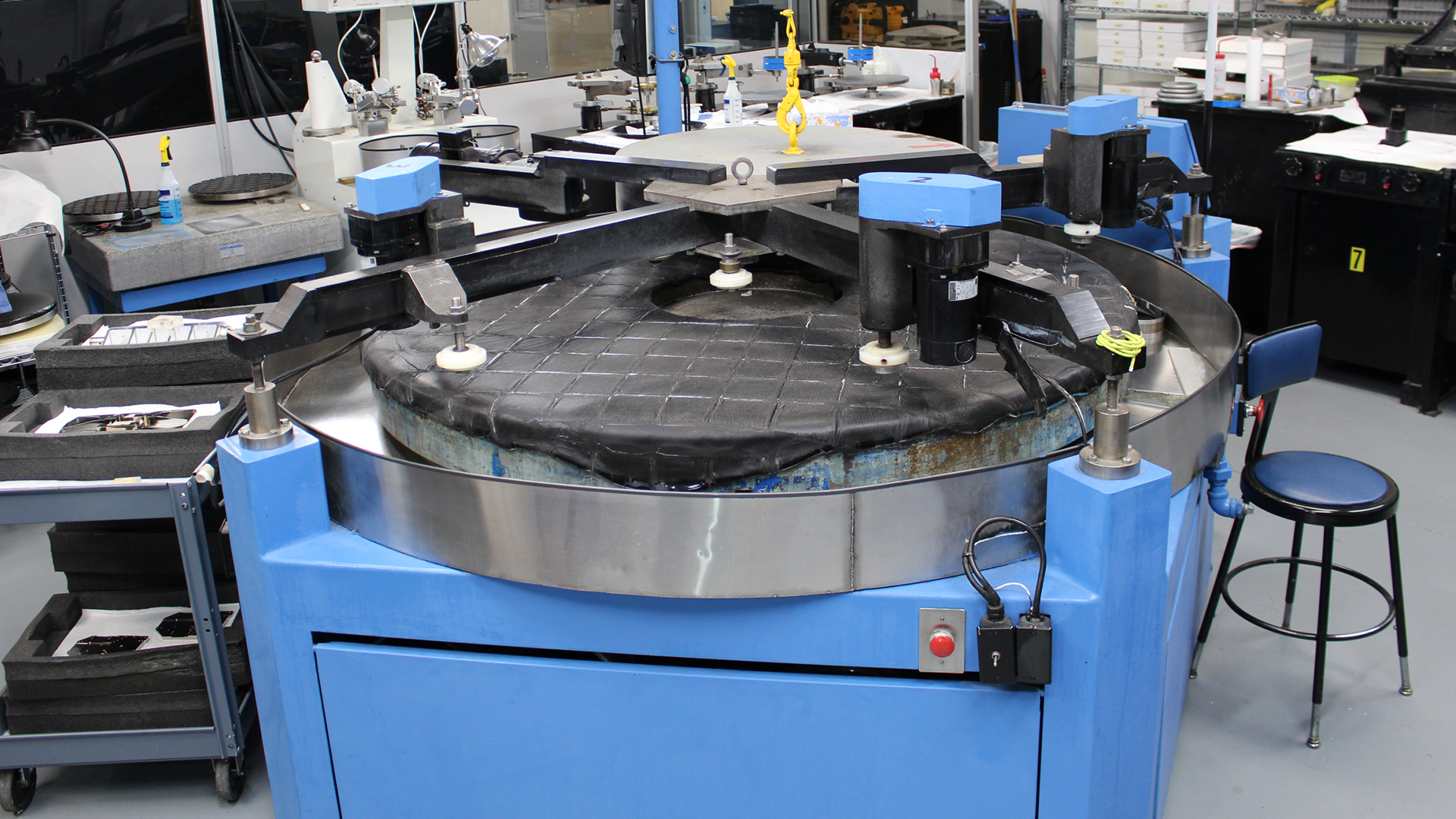

- Polishing / Grinding Machines

- 72” Strasbaugh Planetary Polisher

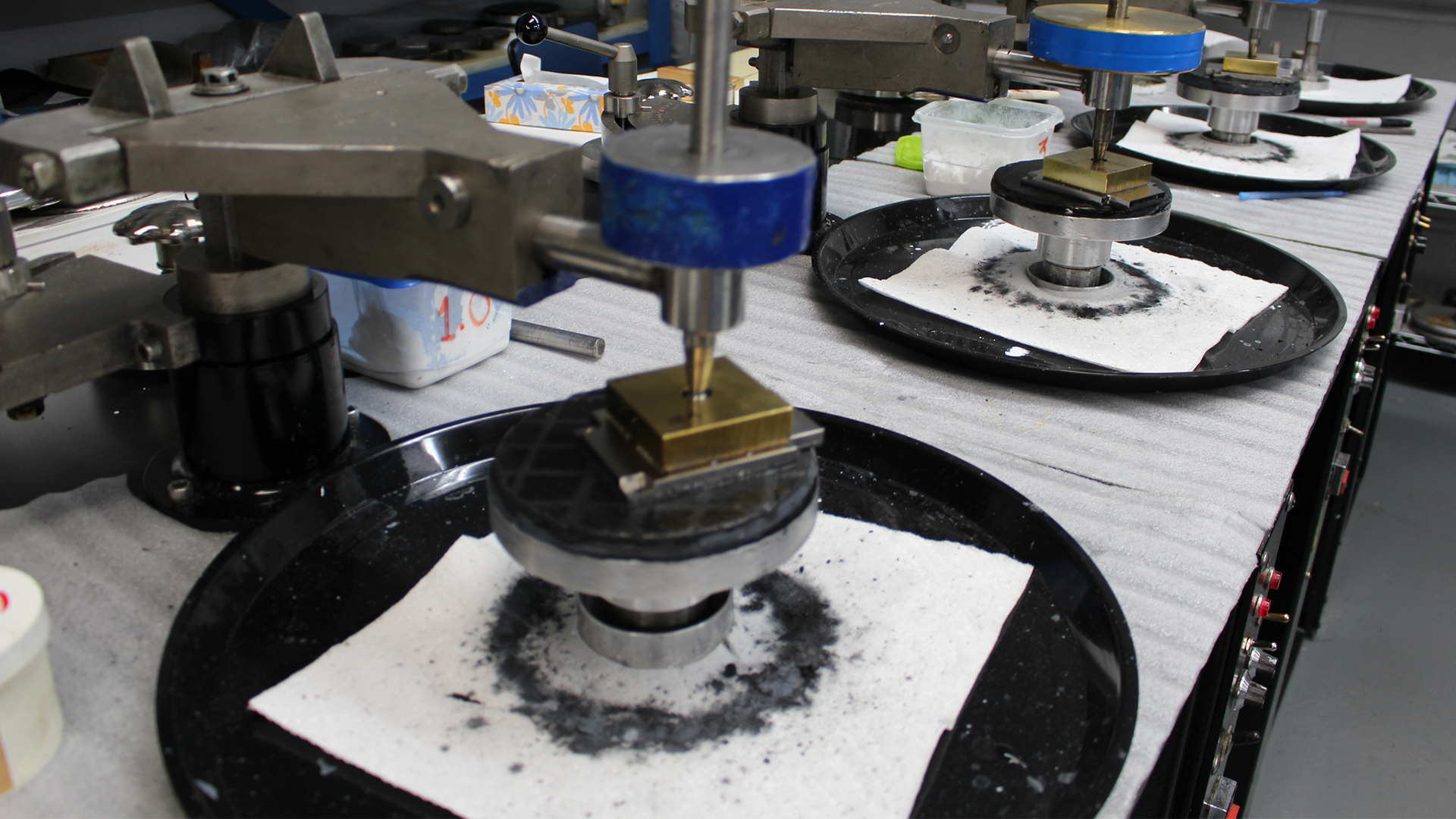

- 9 Single Spindle Polishing / Lapping Machines

- Dual Spindle Polishing / Lapping Machine

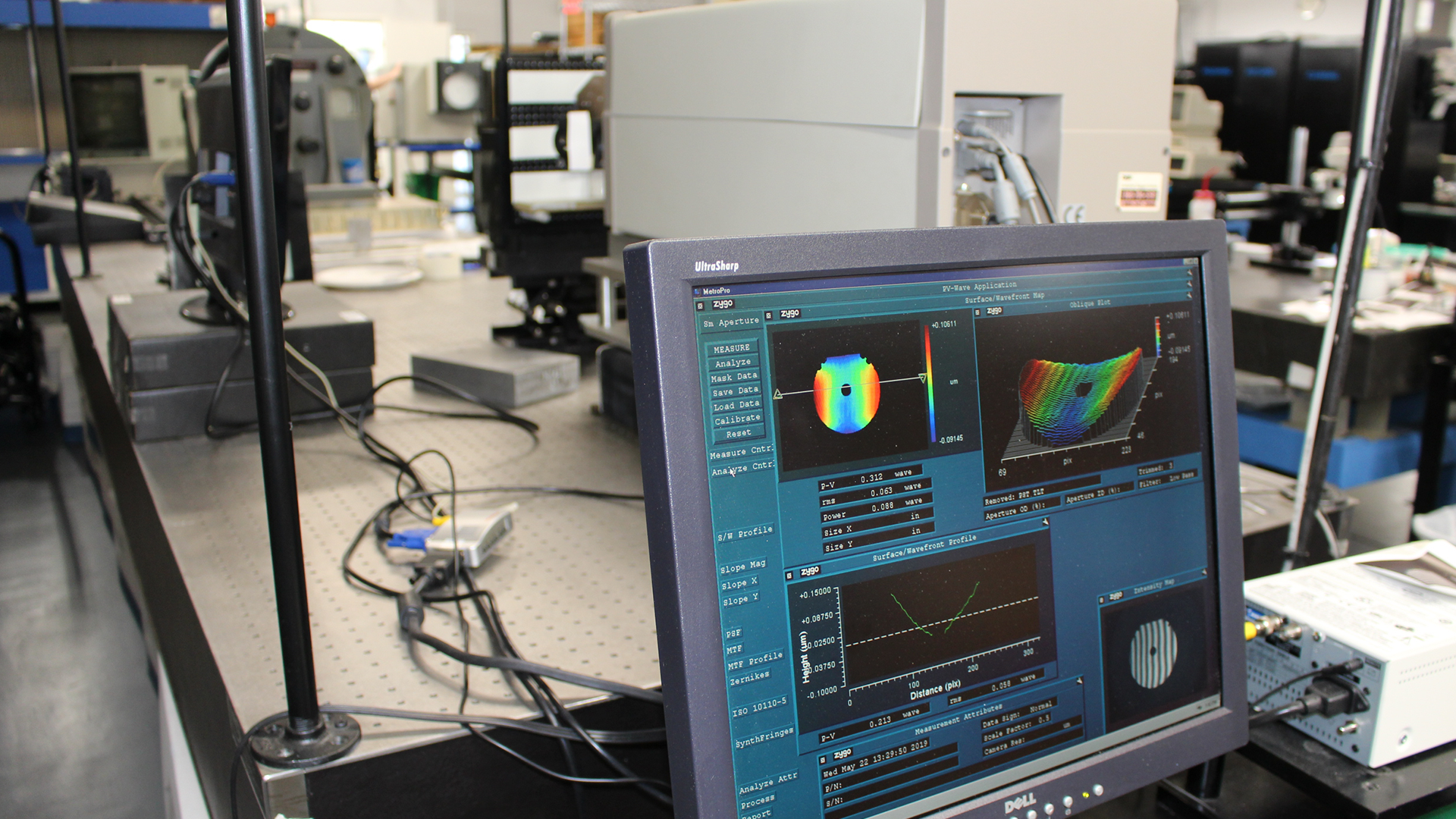

The components can be as large as 15 inches in length, meeting optical requirements of 1/8 wave PV or better, depending on part geometry, and 40-80 angstroms RMS for surface roughness. MOI’s Diamond Turning Machines ensure tight angular requirements for polygons or scanner optics. The Machine Controllers have been upgraded for quick repairs, with added expansion slots for future upgrades.

Diamond Turning Materials

Materials used by Manasota Optics include Bare Aluminum, Copper, Silver, Invar, Brass, and Nickel Plated Aluminum for various applications. These machines produce Plano (Flat) Optics up to 15” in length, meeting 1/8 Wave PV, 40-80 Angstroms RMS, and tight angular tolerances.

With upgraded controllers and a focus on precision, MOI’s Services amd Capabilities stand ready to meet the demands of various industries, from aerospace to telecommunications.

Our Mission

Our mission is to provide our customers products that are second to none in our industry. The vast experience with metal optics that we possess has allowed us to evaluate our customer’s design for manufacturability which in return creates a functional, but cost-efficient product that is delivered to our customers when promised.