Services and Capabilities

Manasota Optics, Inc. (MOI) is a “build to print” manufacturer of metal optical components that are used in the Defense and Aerospace Sector. MOI fabricates optics that are used in various sighting systems in military vehicles, laser rangefinders, targeting and infrared countermeasure systems, scanners, biological & chemical detection systems and space applications. We offer a wide range of services and capabilities to meet your needs.

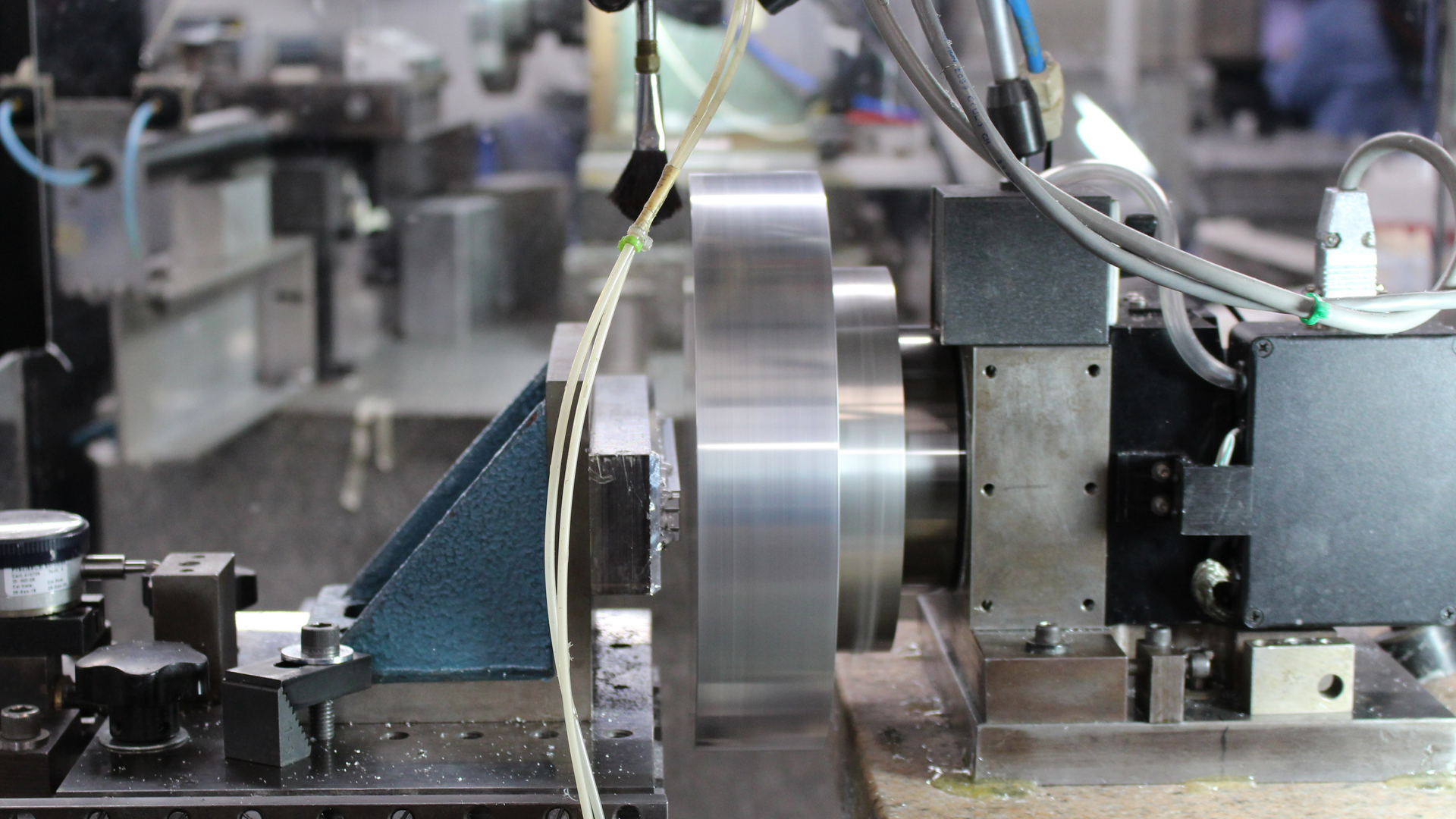

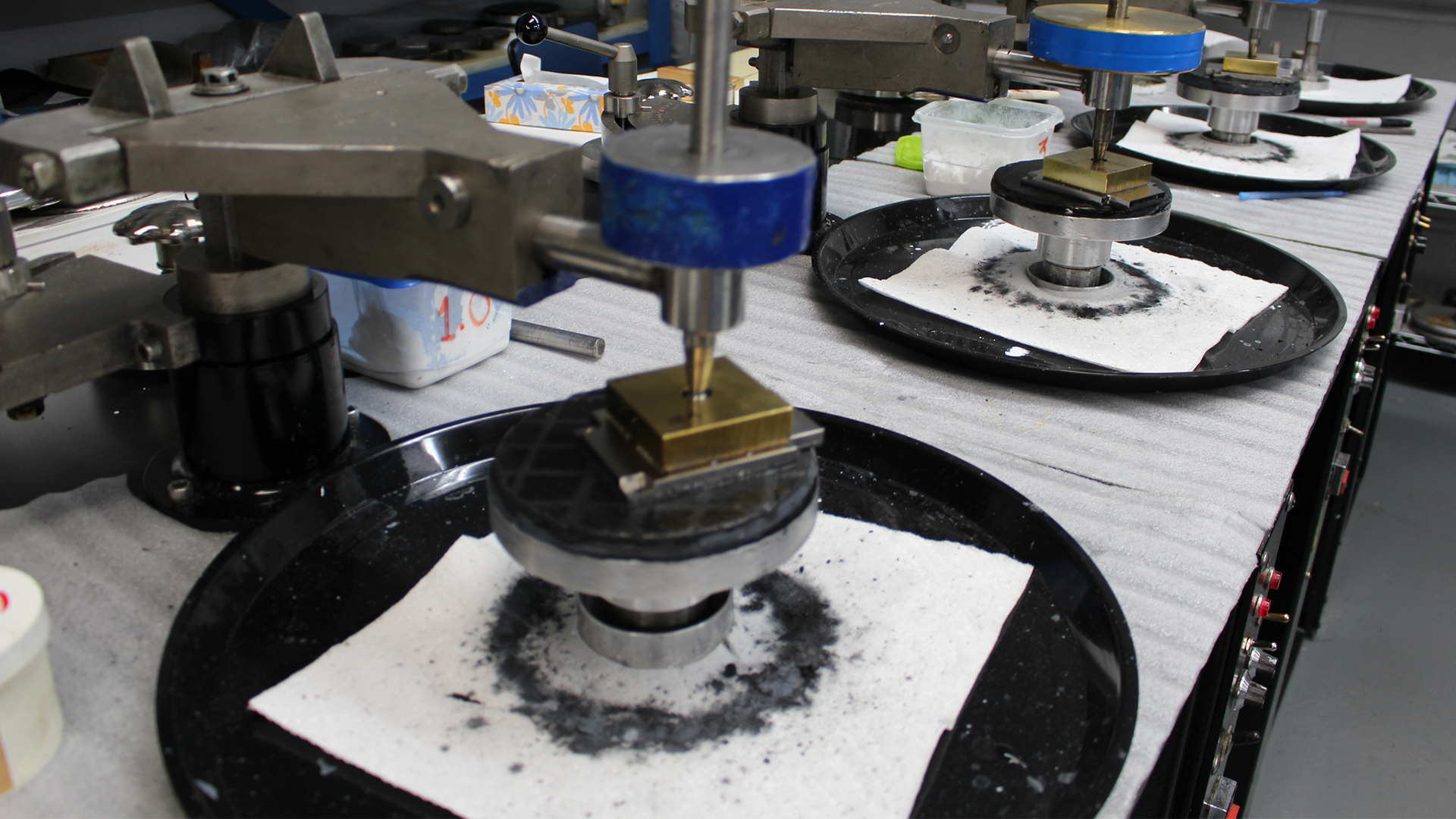

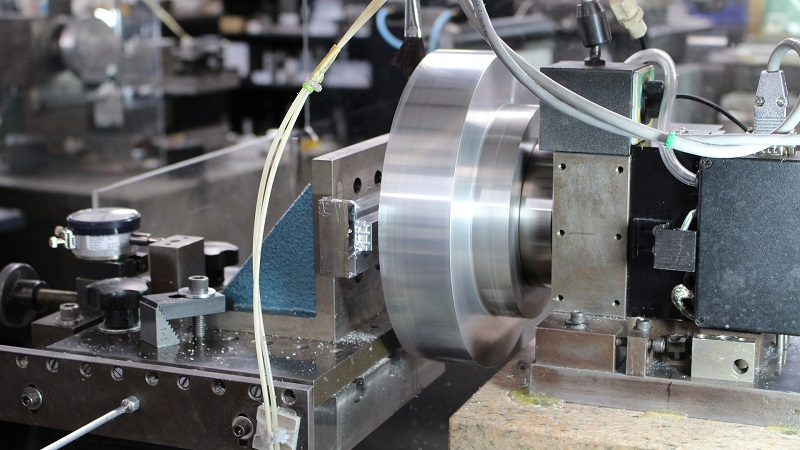

Diamond Turning

Manasota Optics’ Diamond Turning Equipment is made up of Custom-Built Single Point (SPDT) “Fly-Cutting” Machines. These machines work with a variety of materials, including Bare Aluminum 6061, 5052, and 7075, Electroless Nickel Plated Substrates, Copper, and Invar, to produce “plano” or flat optics.

- 6 SPDT machines with additional machines to be added in the near future

- Upgraded Controllers installed in 2009

- Polishing / Grinding Machines

- 72” Strasbaugh Planetary Polisher

- 9 Single Spindle Polishing / Lapping Machines

- Dual Spindle Polishing / Lapping Machine

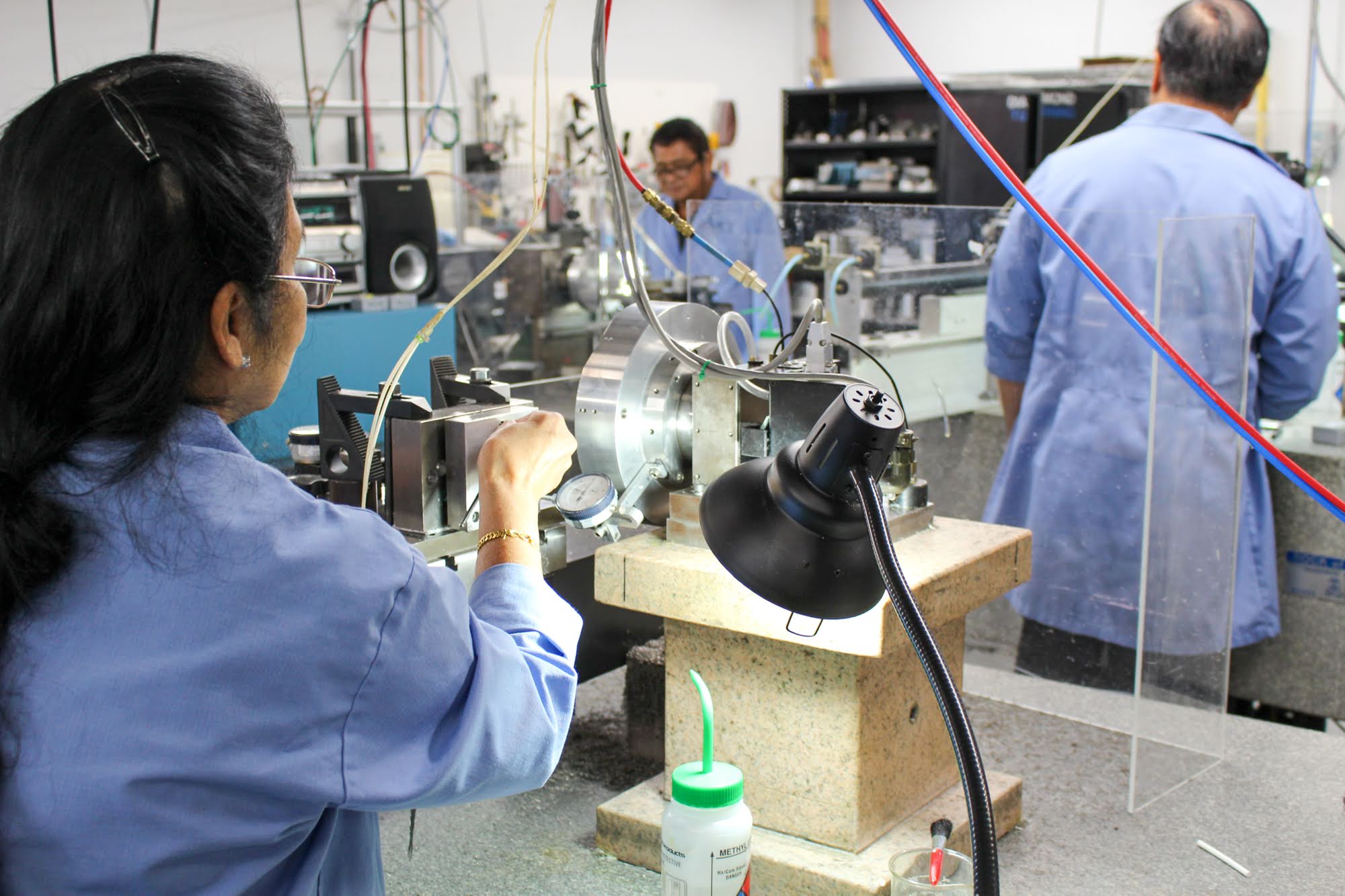

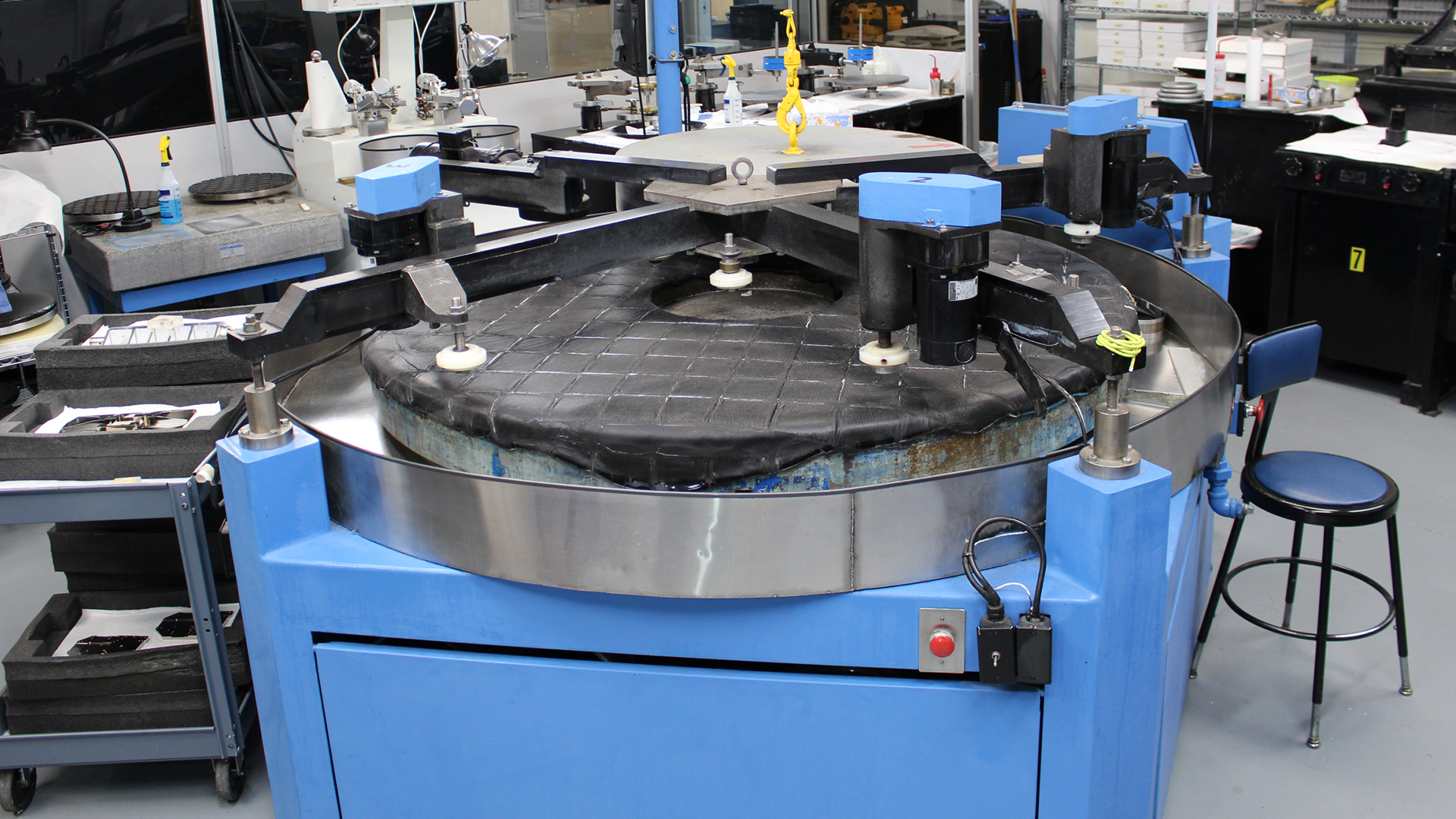

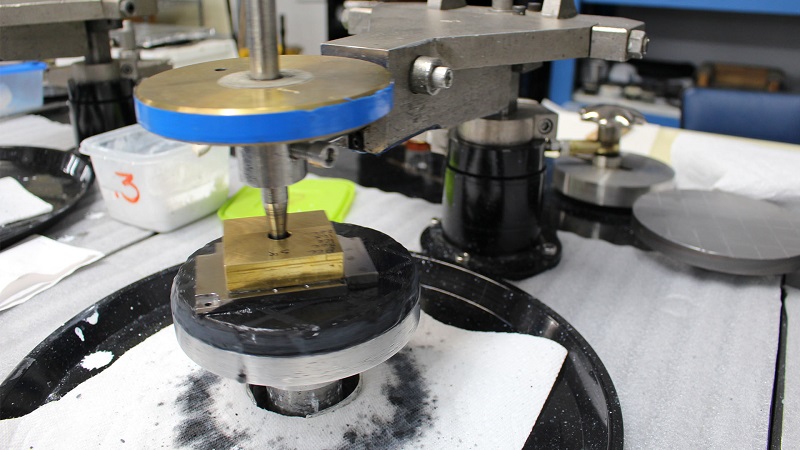

Polishing and Grinding

Manasota Optic’s Polishing and Grinding services can produce “plano” or flat optics as well as spherical components. The sizes of components can range up to 24″ in diameter and the optical requirements are typically 1/8 wave or better PV and 20-40 angstroms RMS for surface roughness.

- 72″ Strasbaugh Planetary Polisher

- 9 Single Spindle Polishing / Lapping Machines

- 1 Dual Spindle Polishing / Lapping Machine

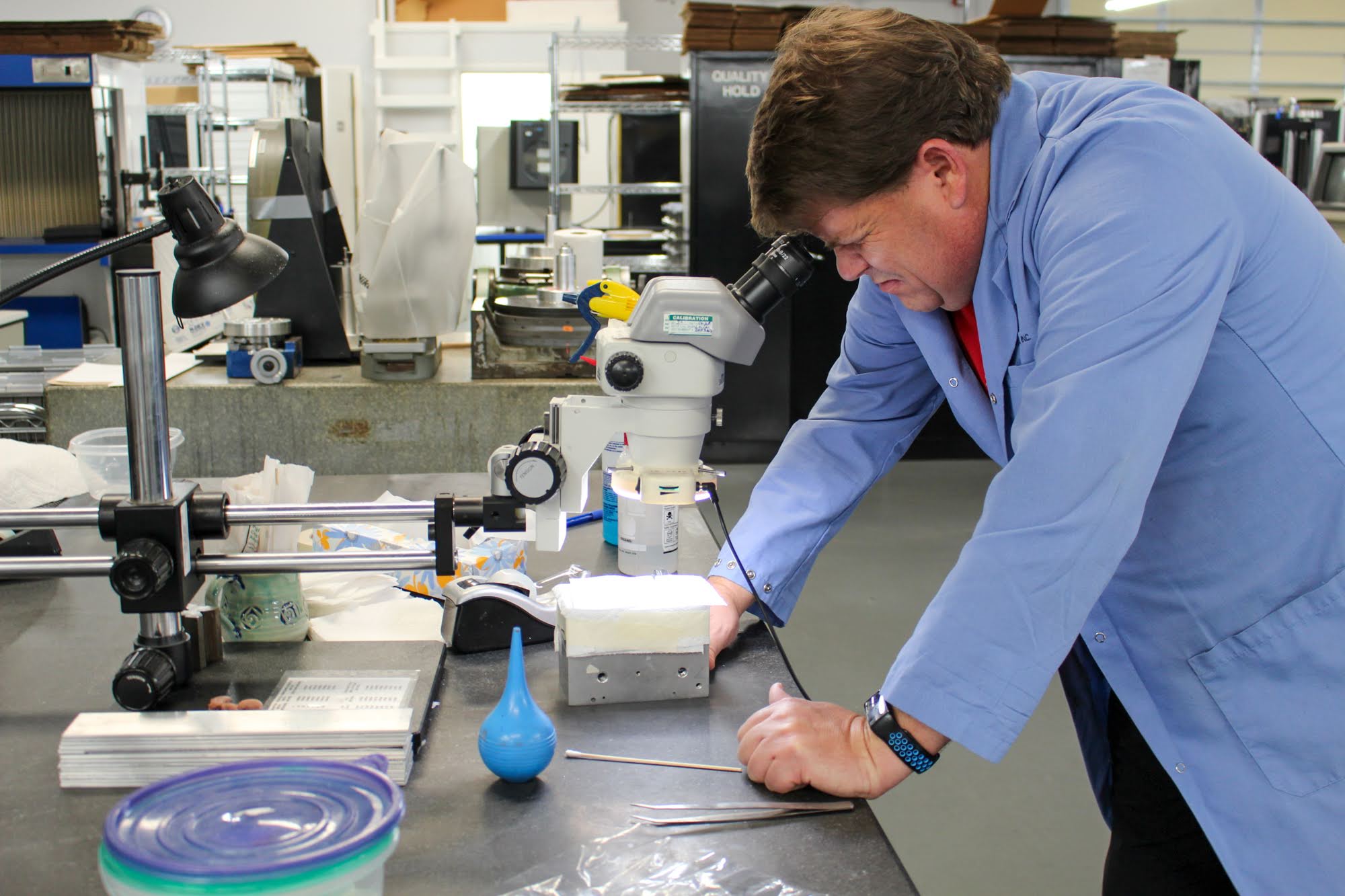

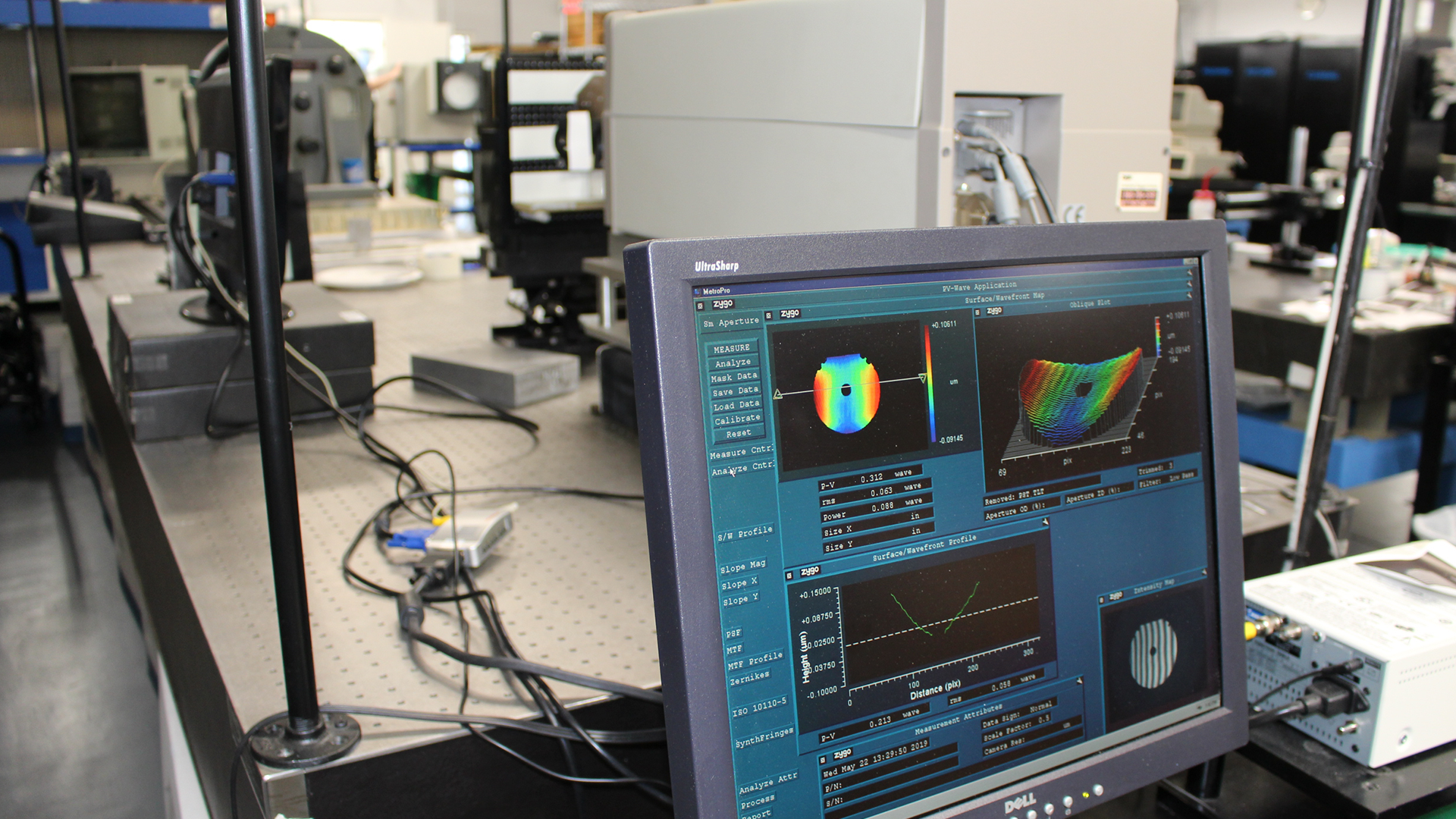

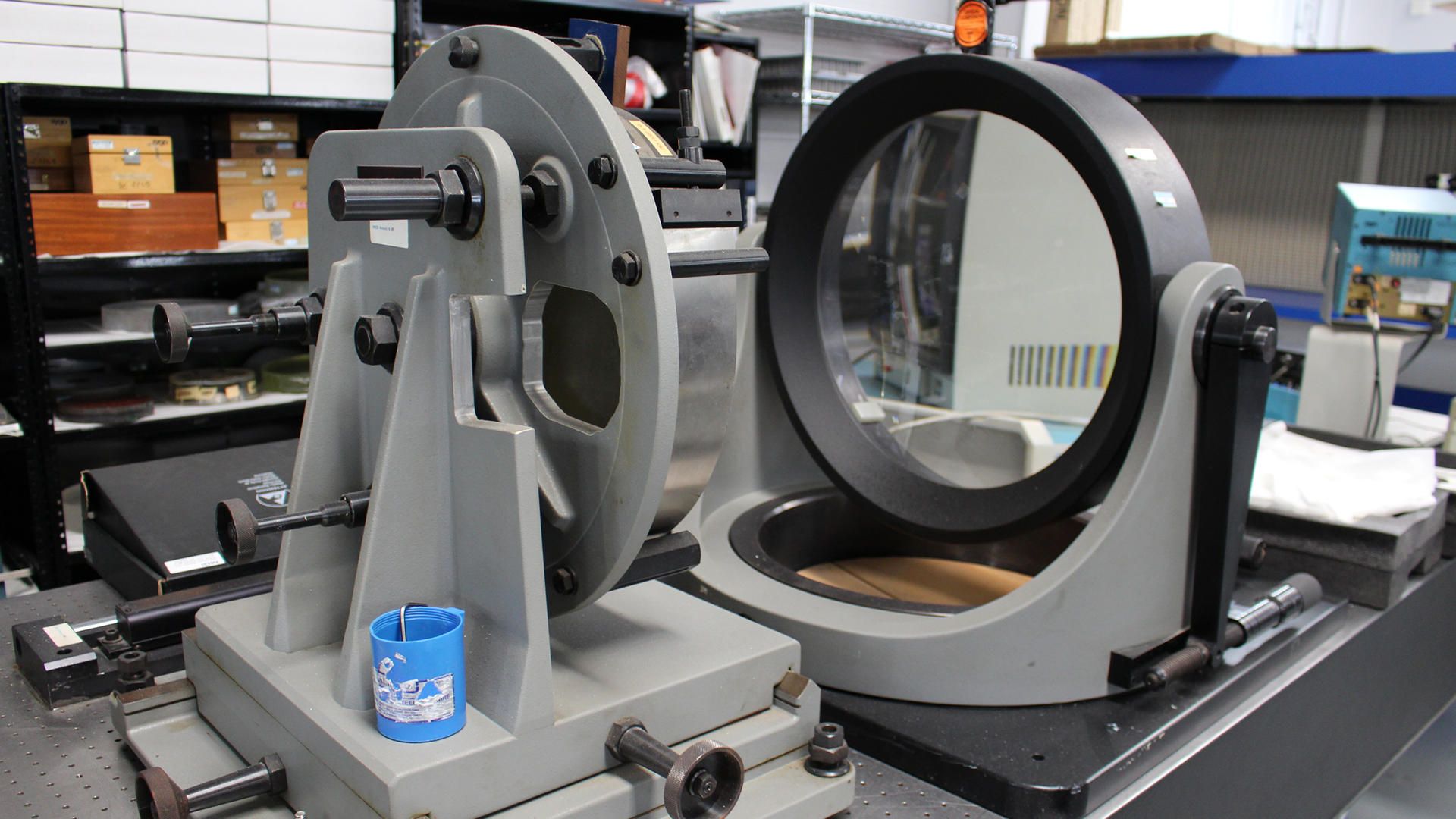

Metrology and Optical Equipment

- Zygo® GPI-XP Phase Shift Interferometer Capable of measuring up to 6” diameter area

- Zygo® 6″ Dynaflect Transmission Flat

- Zygo® 4″ Transmission Flat

- Zygo® Transmission Sphere f/0.75

- Zygo® Transmission Sphere f/1.5

- Zygo® Transmission Sphere f/3.3

- Zygo® Transmission Sphere f/7.2

- Zygo® Mark II Interferometer with radius slide attachment

- …and more.

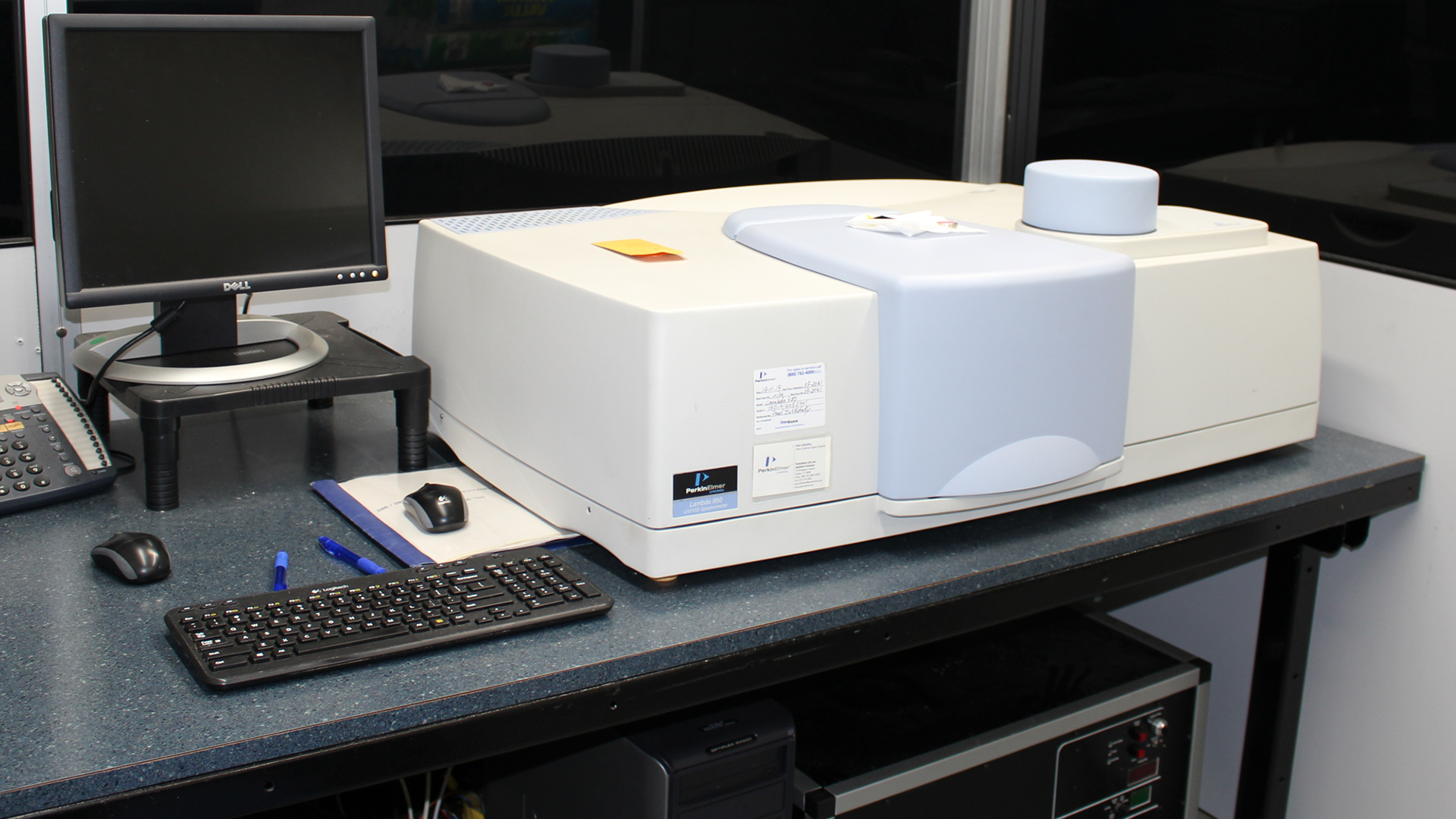

Testing and Environmental Services

- UV, Visible, and Near IR Spectrophometer readings using our PerkinElmer Lambda 950 with the URA Attachment. Coating wavelengths range from 200nm to 3.3 Microns.

- Stress Relieve using our Blue M Oven with temperature extremes from ambient to 500 Degrees F.

- Thermal Cycle using our Tenney TC30 Thermal Chamber with extreme ranges between -100 Degrees F to 212 Degrees F

- Humidity & Thermal Cycle Capabilities with 95% Humidity for 24+ Hours at 120 Degrees F Testing and Thermal Cycle Testing of -100 Degrees F + 375 Degrees with Cincinnati Sub Zero Chamber