Metrology and Optical Equipment

Top-Grade Metrology and Optical Equipment from Manasota Optics, Inc.

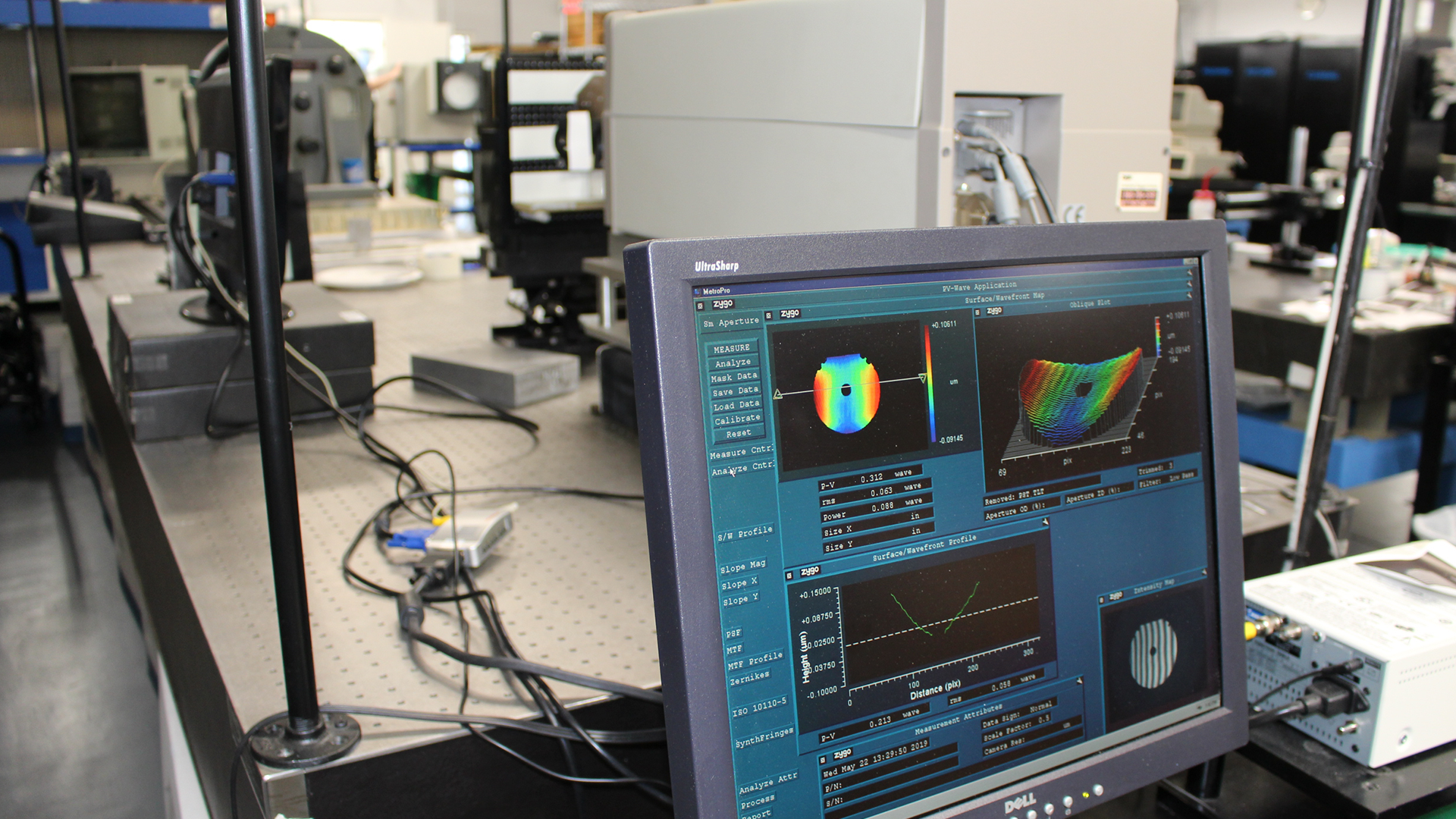

- Zygo® GPI-XP Phase Shift Interferometer Capable of measuring up to 6” diameter area

- Zygo® 6″ Dynaflect Transmission Flat

- Zygo® 4″ Transmission Flat

- Zygo® Transmission Sphere f/0.75

- Zygo® Transmission Sphere f/1.5

- Zygo® Transmission Sphere f/3.3

- Zygo® Transmission Sphere f/7.2

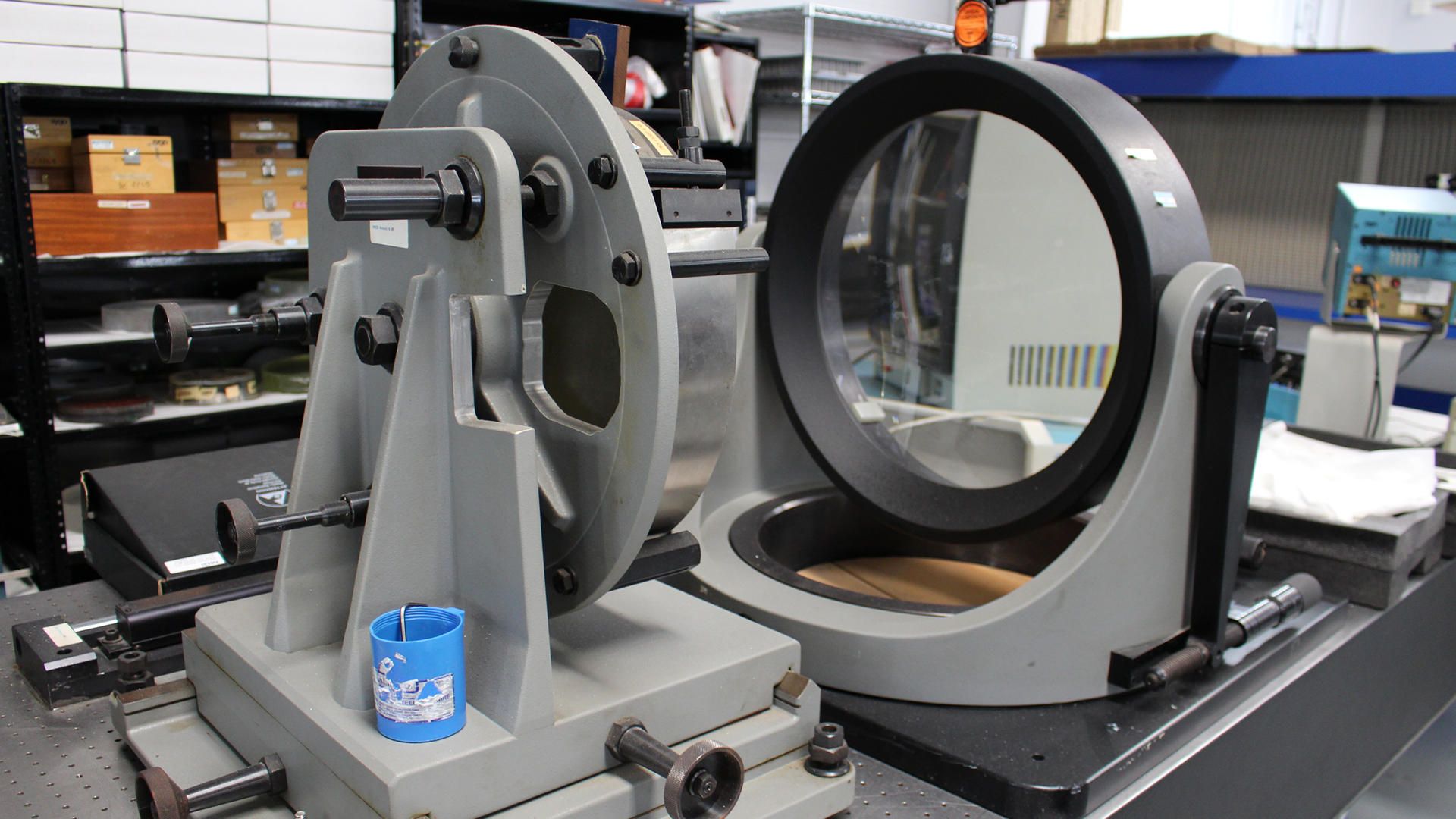

- Zygo® Mark II Interferometer with radius slide attachment

- (2) Zygo® 4-6″ Beam Expanders

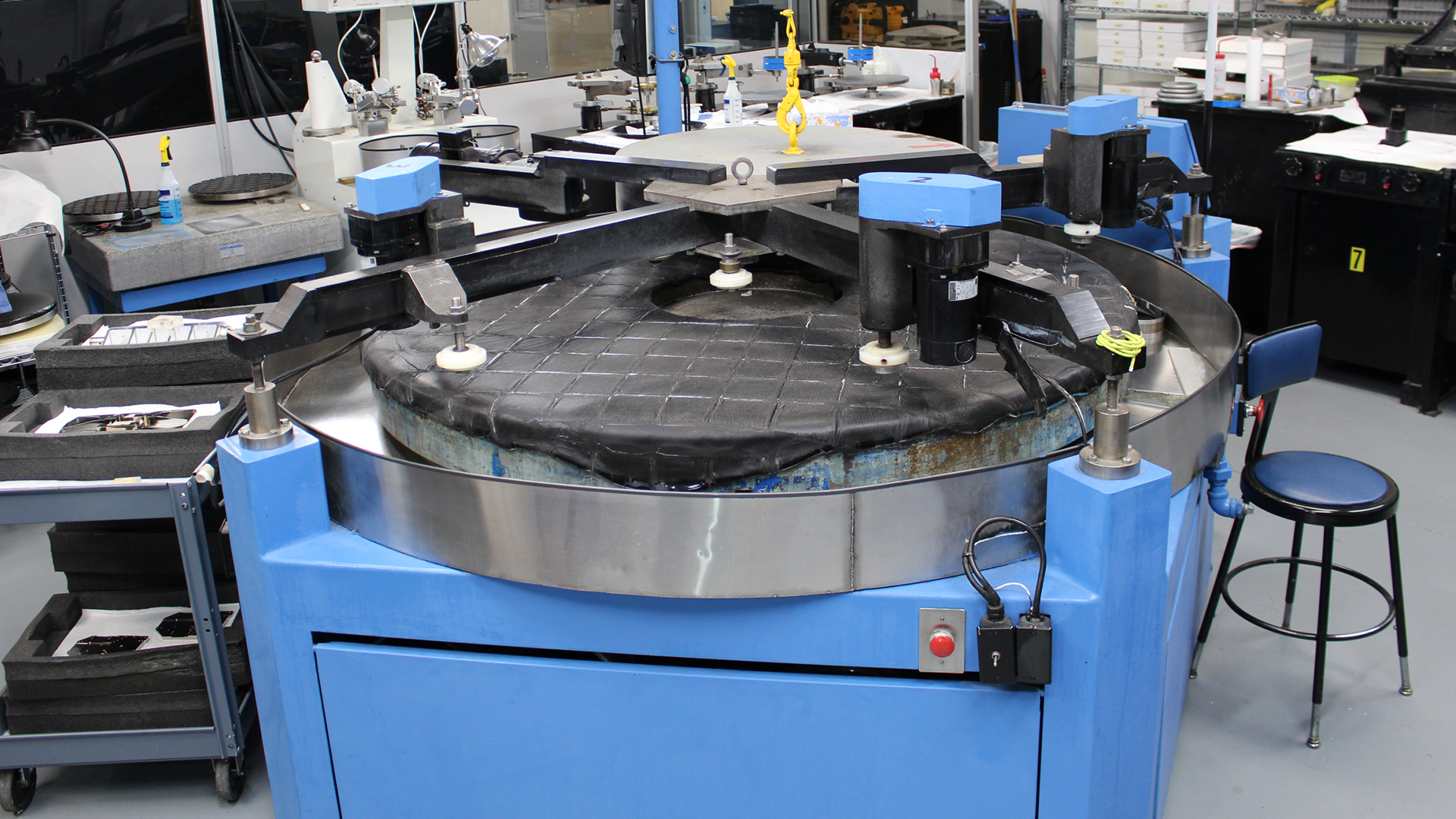

- Newport® 18′ Isolation Table

- Davidson® D-305L Interferometer

- For Larger Optics:

- 18″ Collimating Lens, OSTI

- Davidson 16″ Optical Flat

- Richey Commons Sphere

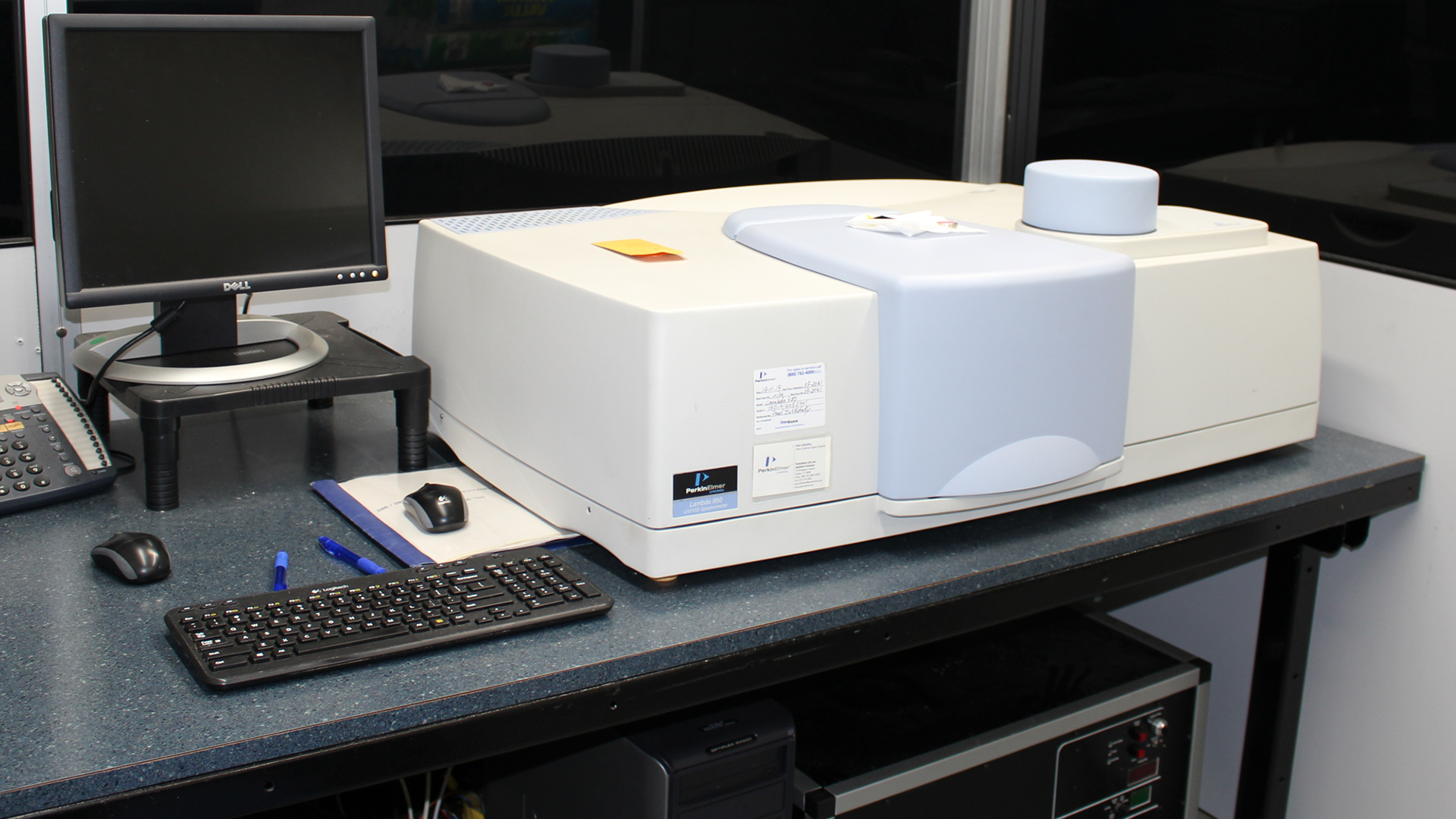

- Perkin Elmer Lambda 950 Spectrophotometer with URA Attachment (Absolute Reflectance Measurement) for Reflectivity ranges from 200nm – 3300nm UV to Near IR

- Perkin Elmer GX Optica FTIR Spectrophotometer for Reflectivity ranges from 1 Micron – 25+ Microns Contains PIKE II Variable Angle Accessory

- WYKO NCP-1000 Non-Contact Profilometer with 20X objective

- Tenney TC-30 Temperature Thermal Chamber with a Watlow F4 Controller and a Honeywell DR4500 Chart Recorder

- Blue M Temperature Stress Relieve Chamber with a Watlow F4 Controller and a Honeywell DR4500 Chart Recorder

- Cincinnati Sub Zero Bench Top Humidity Chamber with a Watlow F4 Controller and a Honeywell DR4500 Chart Recorder

- Nikon 6D Autocollimator with calibrated angle blocks

- Ultradex® – Sub Arc Second Rotary Table

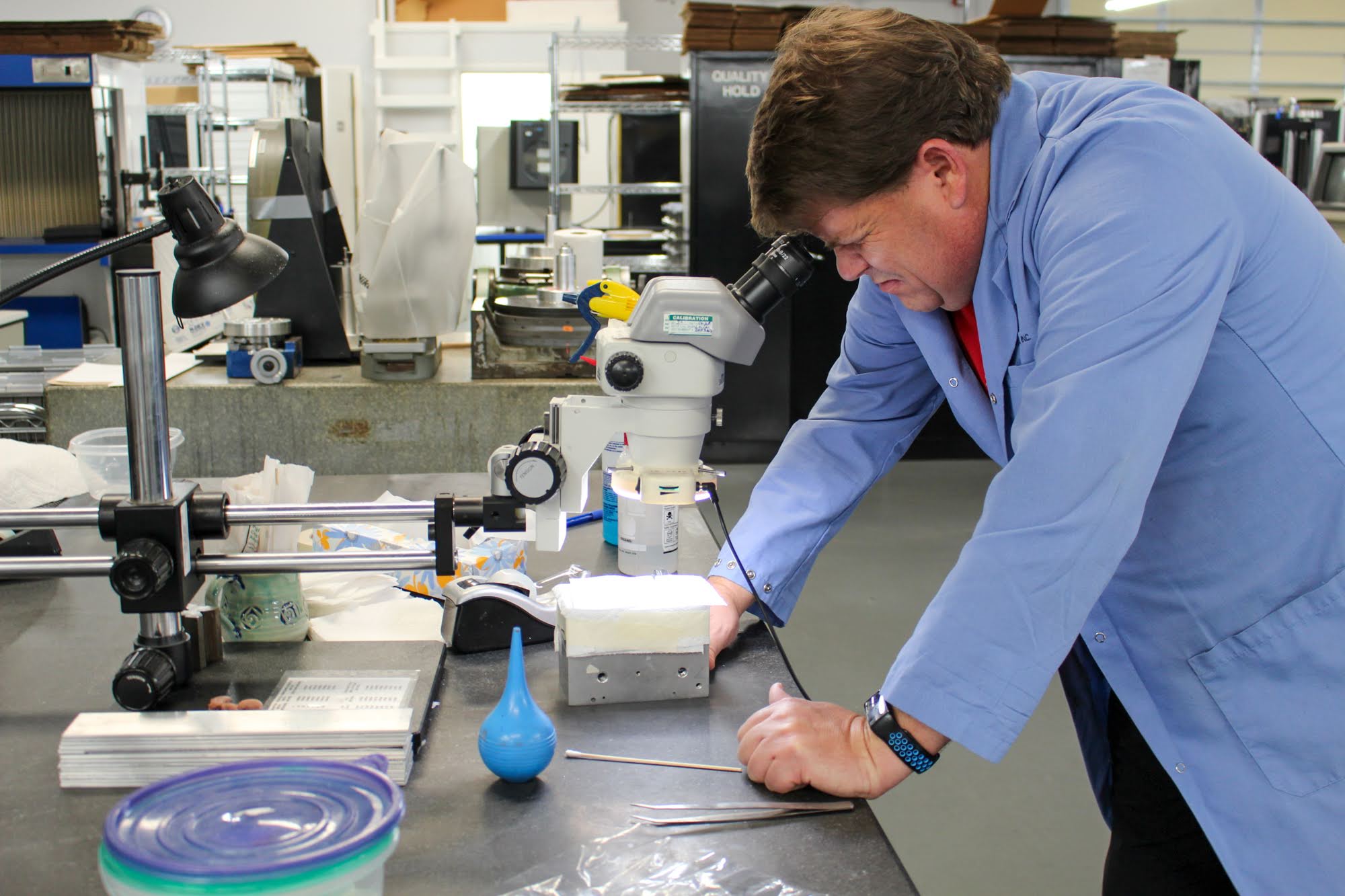

- Nikon SMZ-645 Stereo Microscope with stand. 8X-50X Magnification with calibrated stage micrometer.

- Optical clean flow benches as well as black boxes with 40 watt lighting sources for testing per Military Specifications

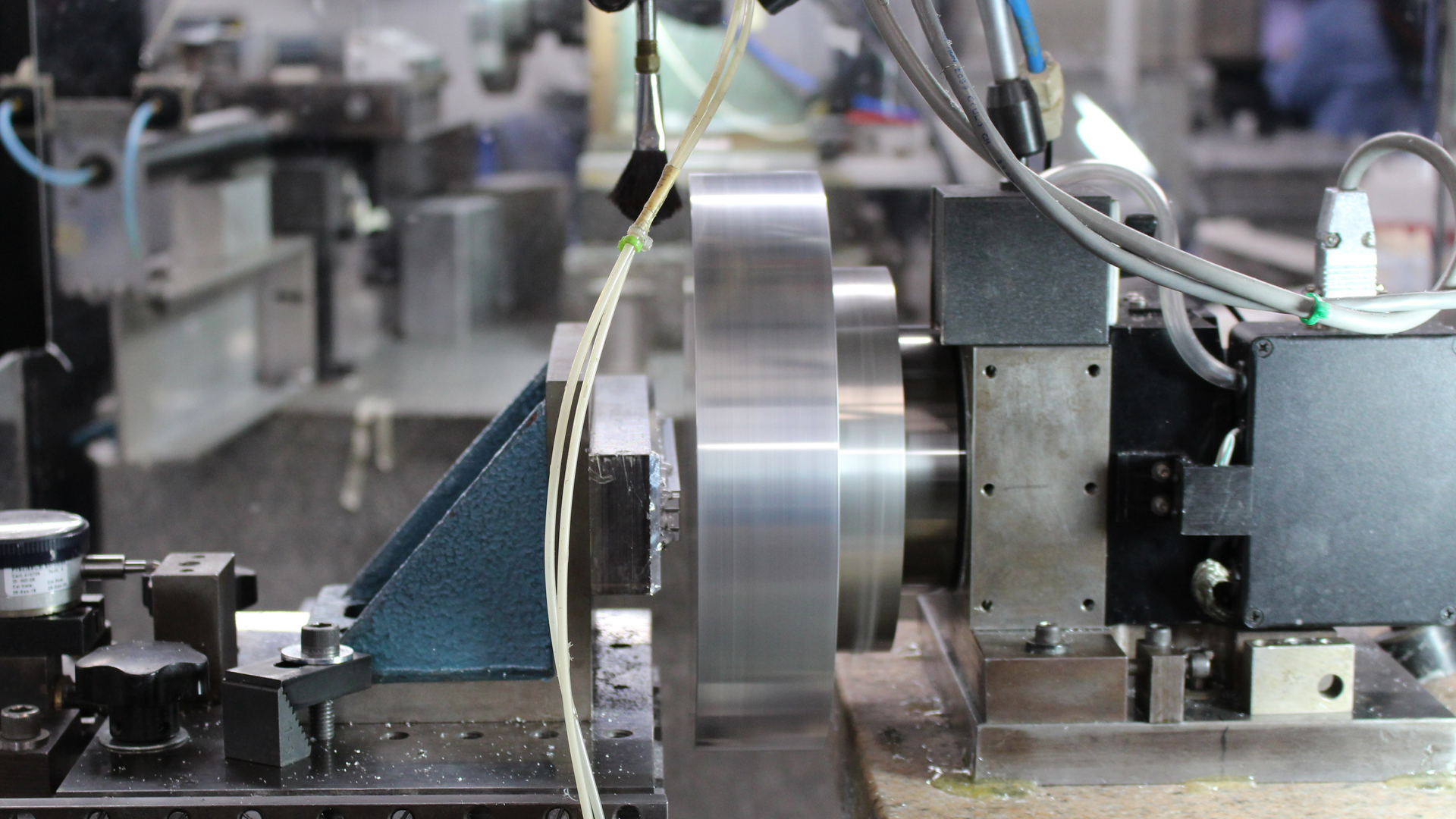

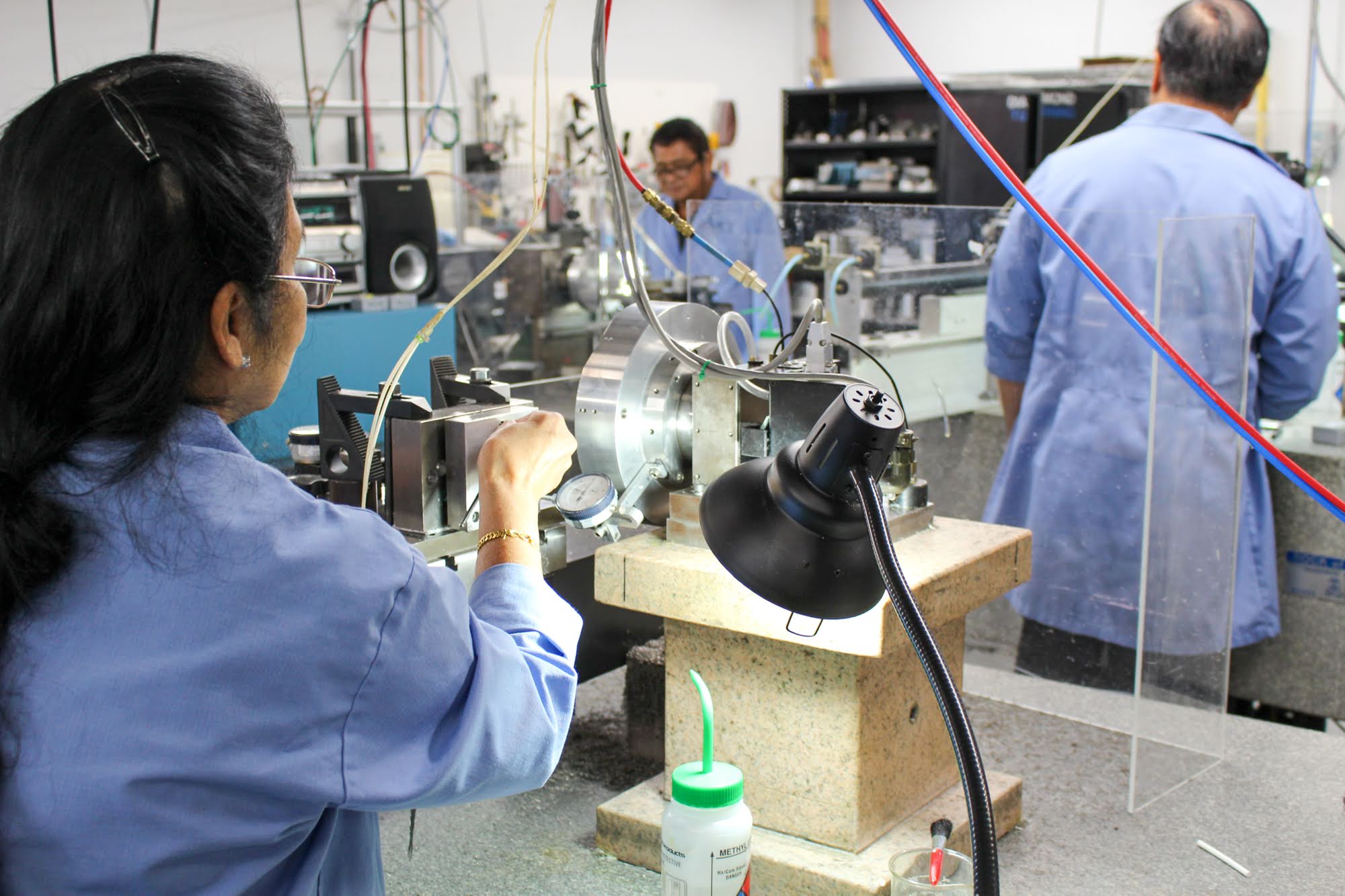

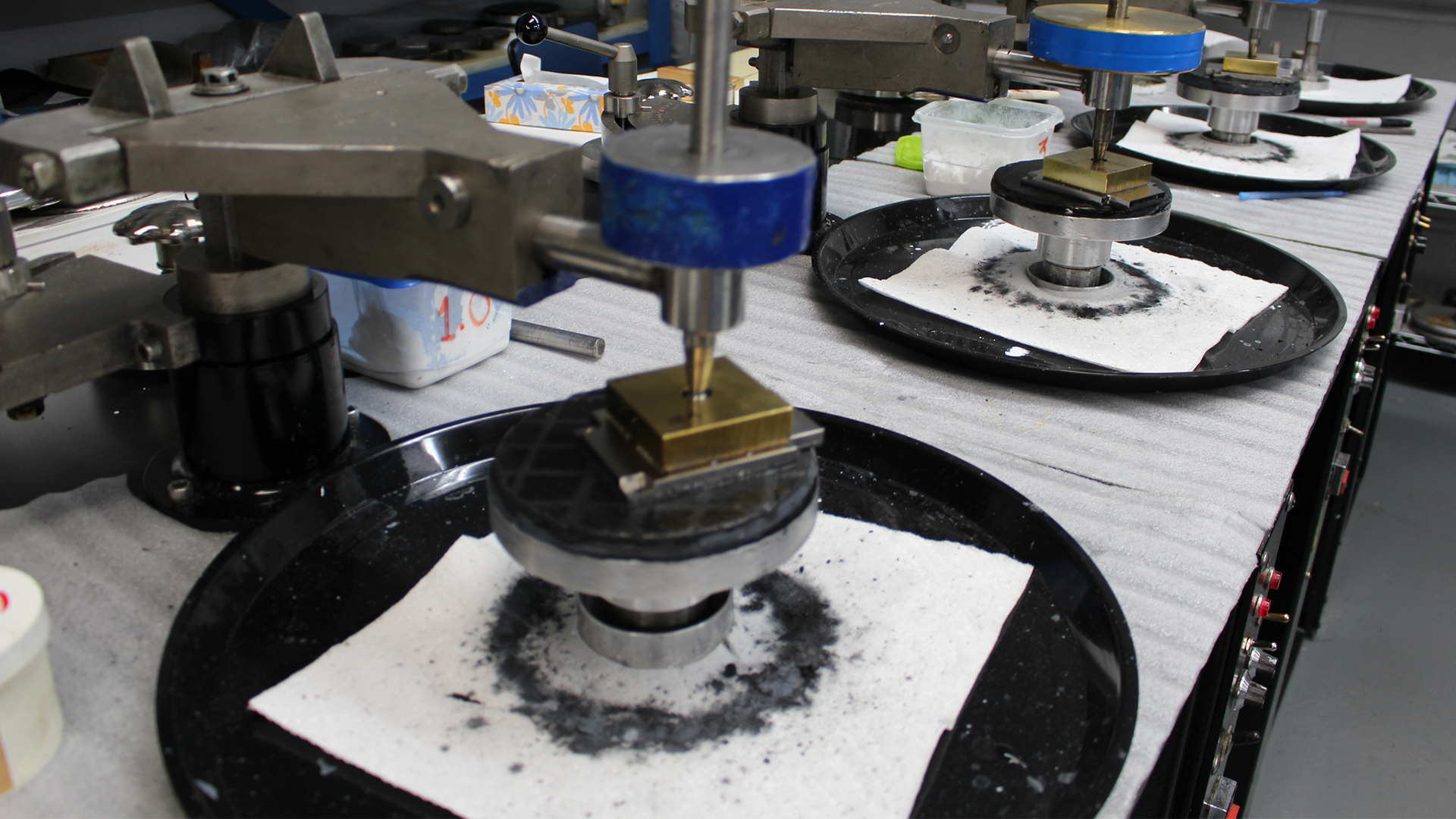

- A variety of optical tooling with testing lenses (both flat and spherical), beam expanders, precision granite surface plates, transmission flats and transmission spheres, half aluminized scratch/dig standards, and precision angle blocks to hold tight tolerances to customer specifications

- Mechanical test equipment consists of micrometers, calipers, dial indicators, threaded gage plugs, and go no-go pins.

- MOI’s mechanical equipment also has precision drop indicators with displays from Heidenhain (MT-25) as well as Mitutoyo.

MOI’s calibration system follows ANSI Z540.3 & ISO10012

Our Mission

Our mission is to provide our customers products that are second to none in our industry. The vast experience with metal optics that we possess has allowed us to evaluate our customer’s design for manufacturability which in return creates a functional, but cost-efficient product that is delivered to our customers when promised.